Leather lamination - Laminating leather

Contents

Lamination on the leather back

Laminating leather means coating or glueing something to the back. This backing can be made with a different type of leather, but also with films, foams or linings. The lamination is done for protective reasons and to reinforce the leather with the properties of the laminated material.

When laminating car or furniture upholstery leather, the entire back of the leather is coated with a laminating material. A lamination material is about 3 to 4 millimetres thick. The adhesive is applied by means of pressure and temperature.

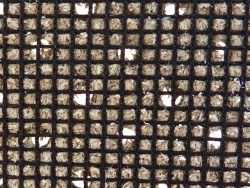

The fabric lamination is well glued.

The leather perforation goes through the glued lamination.

The leather perforation in this case doesn't go through the glued lamination.

The lamination can be made of a wide range of materials.

Fabric lamination behind the perforation.

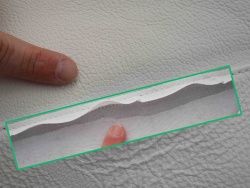

Advantages of this lamination: Real leather can stretch over time. The leather becomes wavy and bumpy. The lamination prevents this happening. In addition, the lamination facilitates the formations of special shapes and replaces the otherwise conventional cushioning wool.

The lamination makes it possible to achieve special shapes more easily.

Stretch leather

In the case of stretch leather, a flexible fabric is laminated to the back of the leather.

Leather trousers made of laminated stretch leather.

Colour migration

When laminating, care must be taken to ensure there is no possibility of dye transfer. Dyed textile fabrics can lead to colour migration from the fabric. Over time these dyes penetrate through the leather and can show up on the upper surface.

Colour migration in the area of back lamination with a dark fabric.

Colour migration or adhesive migration in the area of back lamination with a white fabric.

Additional information

a kotori web solution

a kotori web solution