Difference between revisions of "Boarded leather - Boarded grain"

From www.leather-dictionary.com - The Leather Dictionary

| Line 5: | Line 5: | ||

==Boarded leather - Boarded grain== | ==Boarded leather - Boarded grain== | ||

| − | Boarding is a | + | Boarding is a leather production process designed to reinforce and emphasise the [[Leather grain - Grain side|grain of the leather]]. The [[leather production|tanned]] and [[leather colour|dyed]] leather is rolled under pressure over an edge. The [[grain side]] is thereby on the inside (facing the board)and is compressed. The resulting folds in the leather are as durable as an [[Embossed leather|embossing]]. The leather can be boarded from several directions, thus giving different [[Leather grain - Grain side|grain textures]]. |

| Line 40: | Line 40: | ||

! bgcolor=#eeeeee | Process steps in the [[leather production]] | ! bgcolor=#eeeeee | Process steps in the [[leather production]] | ||

|- | |- | ||

| − | | bgcolor=#ffffff align=center | [[storage of leather| | + | | bgcolor=#ffffff align=center | [[storage of leather|Storage]] - [[soaking]] - [[Liming - Leather Tanning|liming]] - [[Fleshing - Making of leather|fleshing]] - [[Split leather|splitting]] - [[pickling]] - [[Tanning leather|tanning]] - [[neutralising]] - [[Drying leather|withering]] - [[Leather production#Sorting|sorting]] - [[shaving]] - [[Leather production#Dyeing (through colouring) and fatliquoring|dyeing (through colouring) and fatliquoring]] - [[Drying leather|drying]] - [[finish]] - [[softening]] - [[Leather quality|final check]] |

|} | |} | ||

</center> | </center> | ||

Revision as of 13:47, 24 March 2017

Boarded leather - Boarded grain

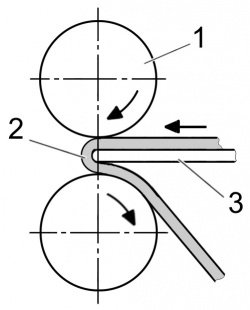

Boarding is a leather production process designed to reinforce and emphasise the grain of the leather. The tanned and dyed leather is rolled under pressure over an edge. The grain side is thereby on the inside (facing the board)and is compressed. The resulting folds in the leather are as durable as an embossing. The leather can be boarded from several directions, thus giving different grain textures.

Schematic description of the boarding. 1: roller, 2: leather, 3: boarding sheet edge.

Flat and grainless patent leather turned into boarded leather.

Epi leather is a type of grain from Louis Vuitton which embossing reminds of boarded leather.

Epi leather-embossing of Louis Vuitton in Moscow.

| Process steps in the leather production |

|---|

| Storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing (through colouring) and fatliquoring - drying - finish - softening - final check |

a kotori web solution

a kotori web solution