Difference between revisions of "Corrected grain"

| Line 4: | Line 4: | ||

| − | == | + | ==Leather surface corrected Grain== |

| − | In preparation for [[Embossed leather|embossing]] [[smooth leather]], the leather is frequently [[Sanding leather|sanded (buffed)]] first on the grain side to obtain a uniform surface and to make [[Natural markings on leather|skin damages]] invisible. Subsequently, a [[finish|binder-based colour layer]] is applied and a uniform [[Leather grain - Grain side|grain]] [[Embossed leather|embossed]]. | + | In preparation for [[Embossed leather|embossing]] [[smooth leather]], the leather is frequently [[Sanding leather|sanded (buffed)]] first on the grain side to obtain a uniform surface and to make [[Natural markings on leather|skin damages]] invisible. Subsequently, a [[finish|binder-based colour layer]] is applied and a uniform [[Leather grain - Grain side|grain]] [[Embossed leather|embossed]]. The [[Finish#Primer - Finish/Top Coat|application of the colour layer]] is carried out by a roller coater and more rarely by spraying. |

Such leather is then referred to as "Corrected Grain". It is cheaper and feels [[Haptic evaluation of leather surfaces|stiffer and colder]] due to the thick colour layer and the fibre compression of the embossing. It is also less [[Breathability of leather|breathable]] than [[porous leather]]. | Such leather is then referred to as "Corrected Grain". It is cheaper and feels [[Haptic evaluation of leather surfaces|stiffer and colder]] due to the thick colour layer and the fibre compression of the embossing. It is also less [[Breathability of leather|breathable]] than [[porous leather]]. | ||

Revision as of 07:16, 24 July 2023

Leather surface corrected Grain

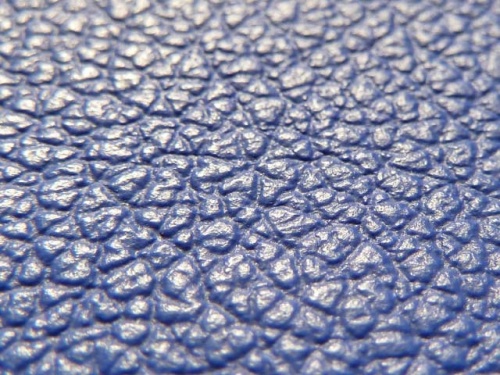

In preparation for embossing smooth leather, the leather is frequently sanded (buffed) first on the grain side to obtain a uniform surface and to make skin damages invisible. Subsequently, a binder-based colour layer is applied and a uniform grain embossed. The application of the colour layer is carried out by a roller coater and more rarely by spraying.

Such leather is then referred to as "Corrected Grain". It is cheaper and feels stiffer and colder due to the thick colour layer and the fibre compression of the embossing. It is also less breathable than porous leather.

There are also corrected grains, which are only slightly sanded and embossed and feel soft and warm. But they are rare exceptions.

Embossed and buffed leather. The hair pores are buffed and embossed away.

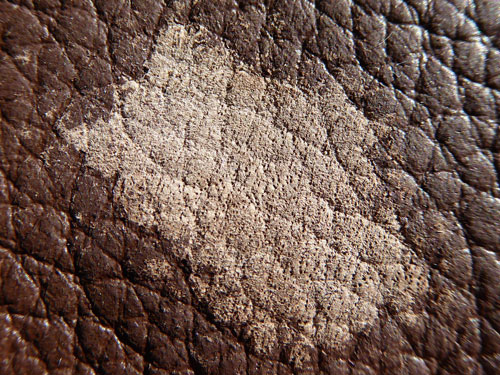

After removing the surface colour layer with a solvent:this leather was buffed, pigmented and embossed with hair pores optic. Visible hair pores alone are not yet a sign of leather quality in the top segment.

Additional information

a kotori web solution

a kotori web solution