Difference between revisions of "Finish"

| (6 intermediate revisions by one user not shown) | |||

| Line 10: | Line 10: | ||

==Finish== | ==Finish== | ||

| − | + | Finishing determines the appearance of the final surface of the leather and the [[leather quality|surface properties]]. This includes [[leather colour|colouring]], [[Waterproofing leather|waterproofing]], [[Pull up leather - Greased leather - Waxed leather - Oiled leather|wax dressings]], but also mechanical processing stages such as [[Ironing leather|ironing]] or [[Embossed leather|embossing]] of the leather. | |

| − | ==Finishing with pigment containing leather colours== | + | ==Finishing with pigment-containing leather colours== |

| − | To make [[leather]] more [[leather damages|durable]], more [[leather cleaner|stain-resistant]] and permanently [[Waterproofing leather|water-repellent]], a layer of a binder-pigment-mixture is applied to surface of [[smooth leather]] that has already been completely | + | To make [[leather]] more [[leather damages|durable]], more [[leather cleaner|stain-resistant]] and permanently [[Waterproofing leather|water-repellent]], a layer of a binder-pigment-mixture is applied to the surface of [[smooth leather]] that has already been completely pre-coloured with [[leather colour|aniline dyes]]. This colour coat is also called finish or pigmentation. [[Leather suits|Motorcycle suits]], but also many [[Leather jacket|leisure jackets]], [[leather shoes|shoes]], [[car leather|car]], [[leather furniture|furniture]] and [[Leather handbags|bags]] made of [[smooth leather]] have this protective colour layer. These leathers are then referred to as pigmented leather or finished leather. |

| − | [[Smooth leather]] without | + | [[Smooth leather]] without this colour layer is called [[aniline leather]]. Leather with a very thin finish is called [[aniline leather, refined]] or [[Semi-aniline|semi-aniline leather]]. Smooth leather with a finish layer of more than 0.15 millimetres in thickness - whether colour or foil - must be declared as [[Coated leather - Laminated leather|coated leather]] in Europe. |

| − | The advantage of [[aniline leather]] is a [[Haptic evaluation of leather surfaces|warm feel and naturalness]] | + | The advantage of [[aniline leather]] is a [[Haptic evaluation of leather surfaces|warm feel and naturalness]] and the main disadvantage is the sensitivity. Pigmented leather [[Haptic evaluation of leather surfaces|feels colder and firmer]], but is significantly easier to [[leather cleaner|clean]] and [[leather care|care for]] and less sensitive. Pigmented leathers also have lower [[Breathability of leather|breathability properties]] than [[porous leather]]. |

| − | There are also | + | There are also leathers which have an [[Pull up leather - Greased leather - Waxed leather - Oiled leather|oil coating or wax coating]]. For these leathers, uncoloured or dyed waxes and/or oils are applied to the leather surface. Such leather is called [[Pull up leather - Greased leather - Waxed leather - Oiled leather|pull-up leather]]. |

| − | ==Primer - Finish / Top Coat== | + | ==Primer - Finish/Top Coat== |

| − | A [[primer]] is first applied | + | A [[primer]] is first applied to promote adhesion. The top coat, a kind of clear protective coating, is then applied to the subsequent colour layer. Top coats protect the [[leather colour|binder colour]] from [[leather damages|abrasion]] and [[leather damages#Dye transfer on leather|discolouration]] and determine the degree of [[Gloss of leather|gloss]] and the [[Haptic evaluation of leather surfaces|haptic]]. [[Crosslinker|Crosslinkers]] provide [[leather quality|improved fastness]] as additives. In case of particularly [[Gloss of leather|matt]] leather, a duller is added to the top coat and/or to the [[leather colour|colour]]. Vehicle leather is often very matt and leather-covered [[Leather dashboard|dashboards]] must be particularly matt because of the risk of [[Gloss of leather|reflections]] in the windscreen. |

<p align=center> | <p align=center> | ||

| − | <flashow> | + | <flashow>//www.youtube.com/v/DFtRH_aLGL0&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow> |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| Line 39: | Line 39: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Structure of the [[ | + | ''Structure of the [[Leather colour|leather colouring]] and finish. Without finish = [[aniline leather]].''<br></p> |

<p> </p> | <p> </p> | ||

| Line 68: | Line 68: | ||

<p align=center> | <p align=center> | ||

| − | <flashow> | + | <flashow>//www.youtube.com/v/sgvjewIkbZo&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow> |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| Line 82: | Line 82: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Typical top pigmentation on un-dyed [[vegetable-tanned leather]] shimmers brownish when getting [[Antique Leather - Vintage Leather#Leather patina|patina]].''<br></p> | + | ''Typical top pigmentation on un-dyed [[vegetable-tanned leather]] shimmers brownish when getting a [[Antique Leather - Vintage Leather#Leather patina|patina]].''<br></p> |

<p> </p> | <p> </p> | ||

| − | Depending on the thickness of the applied pigment colouration, the [[smooth leather]] is referred to differently. No colour layer: [[Aniline leather]]. Little colour, but [[Leather hair pores - Hair follicles|hair pores]] still | + | Depending on the thickness of the applied pigment colouration, the [[smooth leather]] is referred to differently. No colour layer: [[Aniline leather]]. Little colour, but [[Leather hair pores - Hair follicles|hair pores]] still recognisable: [[Aniline leather, refined]] or [[Semi-aniline|semi-aniline leather]]. Much more colour and [[Leather hair pores - Hair follicles|hair pores]] only little or not recognisable: Pigmented smooth leather. |

| Line 125: | Line 125: | ||

==Problems with deficient finish== | ==Problems with deficient finish== | ||

| − | The finish of a pigmented leather can vary. However, it usually consists of a [[primer]], a colour coat and the top coat. Usually, these layers are additionally | + | The finish of a pigmented leather can vary. However, it usually consists of a [[primer]], a colour coat and the top coat. Usually, these layers are additionally stabilised with a [[crosslinker]]. In case of faulty procedures, this can lead to various problems. |

* If the application area is provided with a type of release agent (fats, oils, silicones, etc.), [[Colour separation of leather|colour separation]] may occur over time. | * If the application area is provided with a type of release agent (fats, oils, silicones, etc.), [[Colour separation of leather|colour separation]] may occur over time. | ||

| − | * The finish consists of several layers. If the waiting time between the steps is too long, it can affect the adhesion. The separation is then not complete, but between individual layers. The cause may be release agents, which are used to prevent adhesive bonds between layered hides. The sooner the next finish layer is applied, the better the binding | + | * The finish consists of several layers. If the waiting time between the steps is too long, it can affect the adhesion. The separation is then not complete, but between individual layers. The cause may be release agents, which are used to prevent adhesive bonds between layered hides. The sooner the next finish layer is applied, the better is the binding. |

| − | * If the applied finish is too soft, it is [[leather damages|wear-sensitive]]. Scratches and abrasions can occur. | + | * If the applied finish is too soft, it is [[leather damages|wear-sensitive]]. Scratches and abrasions can occur. Moisture and fats can enhance such effects. Since leather should ideally be soft and warm to touch, the tanner must find the best solution. |

* If the applied top coat is too thin, the colour rubs off. | * If the applied top coat is too thin, the colour rubs off. | ||

| − | * If the layers are applied too | + | * If the layers are applied too thickly, the leather becomes very [[Haptic evaluation of leather surfaces|plastic-like and feels unnatural and cold]]. |

* If the [[crosslinker]] is missing, the finishing is susceptible to [[leather damages|wear]]. | * If the [[crosslinker]] is missing, the finishing is susceptible to [[leather damages|wear]]. | ||

* If the finish is too hard, this can lead to cracking. When the leather is bent, there are microbreaks which make the leather appear greyish. Usually in the depths of the [[Leather grain - Grain side|grain]]. | * If the finish is too hard, this can lead to cracking. When the leather is bent, there are microbreaks which make the leather appear greyish. Usually in the depths of the [[Leather grain - Grain side|grain]]. | ||

| − | * Too soft or unstable binders can lead to stickiness of the surface. [[Patent leather]] tends to stickiness when getting older. But also | + | |

| + | |||

| + | <p align=center> | ||

| + | [[bild:Cracking-Finish-Leather-01.jpg|250px]] | ||

| + | [[bild:Cracking-Finish-Leather-02.jpg|250px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''A greyish cracking in the folds of the leather appear when the chosen binder is too hard.''<br></p> | ||

| + | |||

| + | |||

| + | * Too soft or unstable binders can lead to stickiness of the surface. [[Patent leather]] tends to stickiness when getting older. But also sunlight can intensify this effect with sensitive leathers. | ||

* If a leather is very [[Gloss of leather|dull]], it can appear greyish. | * If a leather is very [[Gloss of leather|dull]], it can appear greyish. | ||

* If the pigments are UV-sensitive, the leather [[Colour fastness - Light fastness of leather|fades]]. | * If the pigments are UV-sensitive, the leather [[Colour fastness - Light fastness of leather|fades]]. | ||

| Line 164: | Line 174: | ||

<p align=center> | <p align=center> | ||

| − | <flashow> | + | <flashow>//www.youtube.com/v/-qn5R8dKcss&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow><br></p> |

<p align=center> | <p align=center> | ||

| − | '' | + | ''Leather production in a modern [[tannery]].'' |

</p> | </p> | ||

| Line 172: | Line 182: | ||

== [[Leather videos]] about the peculiarities of [[metallic leather|metallic effects]] on leather. == | == [[Leather videos]] about the peculiarities of [[metallic leather|metallic effects]] on leather. == | ||

<p align=center> | <p align=center> | ||

| − | <flashow> | + | <flashow>//www.youtube.com/v/RJJNNu1u2ts&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow> |

</p> | </p> | ||

| Line 180: | Line 190: | ||

! bgcolor=#eeeeee | Process steps in the [[leather production]] | ! bgcolor=#eeeeee | Process steps in the [[leather production]] | ||

|- | |- | ||

| − | | bgcolor=#ffffff align=center | [[storage of leather| | + | | bgcolor=#ffffff align=center | [[storage of leather|Storage]] - [[soaking]] - [[Liming - Leather Tanning|liming]] - [[Fleshing - Making of leather|fleshing]] - [[Split leather|splitting]] - [[pickling]] - [[Tanning leather|tanning]] - [[neutralising]] - [[Drying leather|withering]] - [[Leather production#Sorting|sorting]] - [[shaving]] - [[Leather production#Dyeing (through colouring) and fatliquoring|dyeing (through colouring) and fatliquoring]] - [[Drying leather|drying]] - [[finish]] - [[softening]] - [[Leather quality|final check]] |

|} | |} | ||

</center> | </center> | ||

Revision as of 20:07, 15 June 2019

Contents

Finish

Finishing determines the appearance of the final surface of the leather and the surface properties. This includes colouring, waterproofing, wax dressings, but also mechanical processing stages such as ironing or embossing of the leather.

Finishing with pigment-containing leather colours

To make leather more durable, more stain-resistant and permanently water-repellent, a layer of a binder-pigment-mixture is applied to the surface of smooth leather that has already been completely pre-coloured with aniline dyes. This colour coat is also called finish or pigmentation. Motorcycle suits, but also many leisure jackets, shoes, car, furniture and bags made of smooth leather have this protective colour layer. These leathers are then referred to as pigmented leather or finished leather.

Smooth leather without this colour layer is called aniline leather. Leather with a very thin finish is called aniline leather, refined or semi-aniline leather. Smooth leather with a finish layer of more than 0.15 millimetres in thickness - whether colour or foil - must be declared as coated leather in Europe.

The advantage of aniline leather is a warm feel and naturalness and the main disadvantage is the sensitivity. Pigmented leather feels colder and firmer, but is significantly easier to clean and care for and less sensitive. Pigmented leathers also have lower breathability properties than porous leather.

There are also leathers which have an oil coating or wax coating. For these leathers, uncoloured or dyed waxes and/or oils are applied to the leather surface. Such leather is called pull-up leather.

Primer - Finish/Top Coat

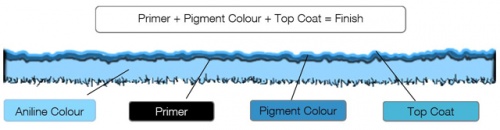

A primer is first applied to promote adhesion. The top coat, a kind of clear protective coating, is then applied to the subsequent colour layer. Top coats protect the binder colour from abrasion and discolouration and determine the degree of gloss and the haptic. Crosslinkers provide improved fastness as additives. In case of particularly matt leather, a duller is added to the top coat and/or to the colour. Vehicle leather is often very matt and leather-covered dashboards must be particularly matt because of the risk of reflections in the windscreen.

Video about different kinds of smooth leather.

Structure of the leather colouring and finish. Without finish = aniline leather.

A water drop on a pigmented smooth leather runs off. The pores of the leather are closed.

In the leather production, the pigmentation is applied by means of rotating spray guns.

The application of a pigment leather colour by leather repair companies is carried out manually with a spray gun.

Car leather was not dyed through until the 70s, 80s. With some leathers, this lead to a beautiful patina.

Typical top pigmentation on un-dyed vegetable-tanned leather shimmers brownish when getting a patina.

Depending on the thickness of the applied pigment colouration, the smooth leather is referred to differently. No colour layer: Aniline leather. Little colour, but hair pores still recognisable: Aniline leather, refined or semi-aniline leather. Much more colour and hair pores only little or not recognisable: Pigmented smooth leather.

Pure aniline leather: Pores are completely visible and there is no finish on the leather.

Semi-aniline leather: Pores are clearly visible, but a thin layer of paint is on the leather surface.

Pores are hardly distinguishable. A stronger colour layer is on the leather surface. Only a leather consultant or expert can investigate whether this leather may still be referred to as semi-aniline leather.

Pigmented smooth leather: Pores

are no longer distinguishable. The leather has a thick layer of paint.

Problems with deficient finish

The finish of a pigmented leather can vary. However, it usually consists of a primer, a colour coat and the top coat. Usually, these layers are additionally stabilised with a crosslinker. In case of faulty procedures, this can lead to various problems.

- If the application area is provided with a type of release agent (fats, oils, silicones, etc.), colour separation may occur over time.

- The finish consists of several layers. If the waiting time between the steps is too long, it can affect the adhesion. The separation is then not complete, but between individual layers. The cause may be release agents, which are used to prevent adhesive bonds between layered hides. The sooner the next finish layer is applied, the better is the binding.

- If the applied finish is too soft, it is wear-sensitive. Scratches and abrasions can occur. Moisture and fats can enhance such effects. Since leather should ideally be soft and warm to touch, the tanner must find the best solution.

- If the applied top coat is too thin, the colour rubs off.

- If the layers are applied too thickly, the leather becomes very plastic-like and feels unnatural and cold.

- If the crosslinker is missing, the finishing is susceptible to wear.

- If the finish is too hard, this can lead to cracking. When the leather is bent, there are microbreaks which make the leather appear greyish. Usually in the depths of the grain.

A greyish cracking in the folds of the leather appear when the chosen binder is too hard.

- Too soft or unstable binders can lead to stickiness of the surface. Patent leather tends to stickiness when getting older. But also sunlight can intensify this effect with sensitive leathers.

- If a leather is very dull, it can appear greyish.

- If the pigments are UV-sensitive, the leather fades.

- Sensitive binders and other chemicals used in finishing can turn yellowish.

- Contamination in the colour or on the leather during paint application or during drying may be visible when dry.

- A too thick colour layer on leathers which tend to looseness, reinforces this effect.

- Aniline dyes in the finish can migrate or transfer dye.

- Amines of upholstery foams or NOx (nitrogen, for example, by exhaust gases from forklift trucks in leather storage) can produce yellowish changes on light finishes.

Additional information

- Crackled leather - Crackle finished leather

- Metallic leather

- Ironing leather

- Glazing leather

- Gloss of leather

- Metamerism

- Micro hollow balls

Videos about the leather production

Leather production in a modern tannery.

Leather videos about the peculiarities of metallic effects on leather.

| Process steps in the leather production |

|---|

| Storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing (through colouring) and fatliquoring - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution