Difference between revisions of "Sanding leather"

m (→Corrected grain) |

|||

| Line 5: | Line 5: | ||

==Sanding leather - Buffing leather== | ==Sanding leather - Buffing leather== | ||

| − | + | Sanding leather involves applying an abrasive paper on a rotating roller to the surface ([[Leather grain - Grain side|grain side]]) or reverse ([[flesh side]]). This results in a uniform surface. In the earlier times of [[leather production]], such work was purely done manually. | |

When sanding the grain side, you get a light velvet-like pile. The leather is then called [[nubuck]]. | When sanding the grain side, you get a light velvet-like pile. The leather is then called [[nubuck]]. | ||

| − | If a [[smooth leather]] is sanded | + | If a [[smooth leather]] is sanded to make the surface smoother, the tanner also calls this buffing. The flat sanding of [[Natural markings on leather|scars]] in the leather, which results in [[nubuck]], is also called buffing. |

| Line 21: | Line 21: | ||

==[[Corrected grain]]== | ==[[Corrected grain]]== | ||

| − | Sometimes, buffing is carried out before applying a [[finish|binder-based pigment colour layer]] and [[Embossed leather|embossing]] the leather. The result is then a [[corrected grain]]. | + | Sometimes, buffing is carried out before applying a [[finish|binder-based pigment colour layer]] and [[Embossed leather|embossing]] the leather. The result is then a [[corrected grain]]. This technique is done to make [[Natural markings on leather|skin damages]] invisible and to obtain a uniform [[Leather grain - Grain side|grain pattern]] in order to reduce the [[Leather cutting waste|cutting waste]]. Such leather is not classed as [[leather quality|superior quality]], because the [[finish]] and the embossing reduces [[Haptic evaluation of leather surfaces|softness and naturalness]]. [[Aniline leather]] and [[Semi-aniline|semi-aniline leather]] are not buffed and are rarely [[Embossed leather|embossed]] and are therefore [[leather quality|higher quality]] and more beautiful leather. |

Some leathers are only slightly buffed and [[Embossed leather|embossed]] and [[Haptic evaluation of leather surfaces|feel beautifully soft and warm]]. But they are an exception. | Some leathers are only slightly buffed and [[Embossed leather|embossed]] and [[Haptic evaluation of leather surfaces|feel beautifully soft and warm]]. But they are an exception. | ||

| Line 35: | Line 35: | ||

| − | To test whether a [[finish|finished]] leather has been sanded | + | To test whether a [[finish|finished]] leather has been previously sanded, the finish must be removed with a solvent. If a [[nubuck|nubuck-like]] surface appears, the leather has been buffed before the [[finish|finish application]]. |

Revision as of 08:59, 27 April 2017

Sanding leather - Buffing leather

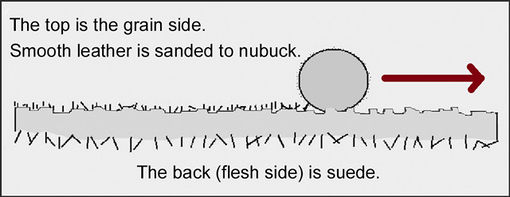

Sanding leather involves applying an abrasive paper on a rotating roller to the surface (grain side) or reverse (flesh side). This results in a uniform surface. In the earlier times of leather production, such work was purely done manually.

When sanding the grain side, you get a light velvet-like pile. The leather is then called nubuck.

If a smooth leather is sanded to make the surface smoother, the tanner also calls this buffing. The flat sanding of scars in the leather, which results in nubuck, is also called buffing.

Nubuck

Nubuck is made by sanding rough (buffing) the grain side.

Corrected grain

Sometimes, buffing is carried out before applying a binder-based pigment colour layer and embossing the leather. The result is then a corrected grain. This technique is done to make skin damages invisible and to obtain a uniform grain pattern in order to reduce the cutting waste. Such leather is not classed as superior quality, because the finish and the embossing reduces softness and naturalness. Aniline leather and semi-aniline leather are not buffed and are rarely embossed and are therefore higher quality and more beautiful leather.

Some leathers are only slightly buffed and embossed and feel beautifully soft and warm. But they are an exception.

Buffed and embossed leather. The hair pores are removed by buffing and embossing.

To test whether a finished leather has been previously sanded, the finish must be removed with a solvent. If a nubuck-like surface appears, the leather has been buffed before the finish application.

Under the colour layer, a slightly roughened surface appears. This leather was buffed.

Under the colour layer, a heavily roughened surface appears. It is coated split leather.

Additional information

a kotori web solution

a kotori web solution