Liming - Leather Tanning

Contents

Liming in the tannery

Liming is one of the main steps carried out during leather production in the tannery. The main purpose of liming is to separate the hair from the hides. Leather is used both with hair (for furs) and without hair. Most of the leather is de-haired in the tannery. Shoes, belts, car and furniture are produced without hairs on the leather.

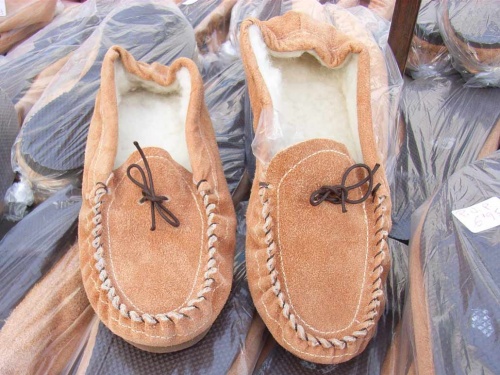

Leather, where the hair remains on the leather skin.

Most leather is processed without hair.

Tasks of liming

- Loosening the top skin and hair, so that it can be removed more easily.

- Loosening of meat and fat residues for removal.

- Removal of proteins that would affect the leather quality.

- Removal of fat in the skin.

- Swelling of the leather fibres.

- Open the skin structure, so that the fibres loosen and the tannins can be well connected.

Liming is done in Europe today with calcium hydroxide and sodium sulfide, which produces waste water that has to be treated in the company's own sewage treatment plants.

Methods of Hair Removal

There are two main methods for removing hair from the skin: "hair removal" and "hair dissolution."

- Hair Removal (Mechanical Method): In this method, the hair is loosened from the skin but left intact. This method uses mechanical forces to separate the previously loosened hair from the skin.

- Hair Dissolution (Chemical Method): In this method, the hair is removed from the skin by chemically dissolving it. Strong chemical substances such as lime or caustic soda are used for this purpose. These substances penetrate the hair structure and dissolve the proteins that make up the hair, completely removing it from the skin.

The choice between the two methods depends on the desired leather surface after tanning. Depending on the method of hair removal with or without preserving the hair, different results in the grain pattern of the leather are obtained.

In many cases, the hair that is preserved during leather hair removal is economically utilized. There are various ways in which the hair can be further used:

- Hair Processing: The hair can be collected, cleaned, and processed to make various products. For example, animal hair is often processed into brushes, paintbrushes, brooms, or upholstery materials. Depending on the type of animal and the quality of the hair, they can also be used for the production of textiles such as felt or carpets.

- Fertilizer: Animal hair can be used as a natural fertilizer. They contain nitrogen and other nutrients that enrich the soil and promote plant growth. Hair can be shredded and incorporated into the soil to improve its fertility.

- Animal Feed: In some cases, animal hair is processed into animal feed. This is usually done for pets or livestock that can use hair as a food source. The hair is specially treated to make it safe for consumption and provide nutritional value to the animals.

The economic utilization of hair depends heavily on the type of animal, the quality of the hair, and local market conditions.

Liming in the drum (bath with lime and sulphur compounds). - After liming the next working steps are fleshing and splitting.

In the past, liming was done with ashes and water.

Videos about the leather production

The leather production in a modern tannery.

| Process steps in the leather production |

|---|

| storage - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing - fatliquoring - retanning - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution