Waterproofing leather

Contents

Waterproofing - Reproofing - Impregnation

Leather is waterproofed or hydrophobic to make it impermeable to water. The same thing is meant with "waterproofed" or "hydrophobic". "hydrophobic" is the expression in the leather production and the end customers speak of "waterproofed leather".

In the tannery, leather exposed to the weather (e.g. shoes and clothing leather) is treated at several points in the manufacturing process in such a way that the best possible waterproofing effect is achieved. Hydrophobic refatting agents are then used for refatting and waterproofing and on pigmented leather water-resistant finishes are then applied. To the best possible leather quality, the tanner has to balance the leather's waterproofness, breathability and naturalness of the leather.

The end user is more familiar with the waterproofing products as aerosol cans or as water-based pump spray products, which are available in every department store or in shoe shops and are used for re-impregnation.

Leather with a pigment finish has a stronger water-repellent property due to the finish. Open-pored leather such as aniline leather or suede and nubuck do not have this protective layer and must therefore be adjusted to be as water-repellent as possible during the manufacturing process.

Laboratory test of the water-repellent properties of a nubuck leather.

Advantages of preventing porous leather from absorbing moisture:

- Breathing activity is reduced when water is drawn in. A completely wet shoe or a completely wet jacket is no longer breathable.

- Feet don't get wet and also the rest of the body is protected from moisture and cold (leather pants, leather jackets, leather hats, leather gloves).

- The leather objects don't get heavy due to penetrating water.

- The stain sensitivity caused by water marks is reduced.

- Sensitive leather looks used and becomes stiffer after becoming soaked.

- Waterproofing treatments can also reduce certain types of soiling.

A surface colouring is the best protection, but the leather does not feel so natural.

Important! A waterproofing never makes a leather as water-repellent as a surface colouration. Waterproofing does not completely protect. Sensitive leather should not be exposed to bad weather, despite waterproofing.

Suede, nubuck and aniline leather should not be exposed to excessive moisture, even with good impregnation!

Important! Waterproofing sprays can damage the lungs. Therefore, always observe the safety instructions. If sprayed outside and not in direct contact with the spray mist, there is no danger. The highest danger is spraying in small, enclosed rooms without ventilation. The lungs don't absorb oxygen, causing suffocation. For this reason products have a strong smell to avoid inhalation.

The most effective are aerosol and solvent-based waterproofing products. At the first treatment, waterproofing must be applied several times and must be sufficiently dried. Heat increases the water-repellent effect.

COLOURLOCK WATERPROOFING SPRAY FOR NUBUCK, SUEDE & FABRICS

COLOURLOCK WATERPROOFING SPRAY FOR NUBUCK, SUEDE & FABRICS

By applying an aerosol water-repellent, the breathability of the leather is reduced by about 5 to 10 percent. Since waterproofing is generally applied to very porous leather, this reduction can be neglected.

Important! Waterproofing is frequently seen as "leather care". However, water-repellents only have the function of preventing water penetration. Leather care is to preserve the good condition of a leather as long as possible. In addition to protecting against the penetration of moisture, leather also needs a re-greasing depending on the type of use, so that it remains soft and/or UV filters, so that it does not fade and/or frictional wearers so that it does not wear so quickly. Therefore, waterproofing should never be considered to be sufficient "leather care", but only as moisture protection. The leather would otherwise dry out and get brittle over time.

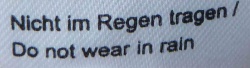

Warning sign for leather pants made of stretch leather.

For very porous aniline leather, an intensive waterproofing is not a sufficient protection. These are "nice-weather" boots.

Waterproofing is unsuitable for surface-coloured leathers. It does not have any care properties despite making them water-repellent. It makes more sense to maintain such leather with a suitable care product.

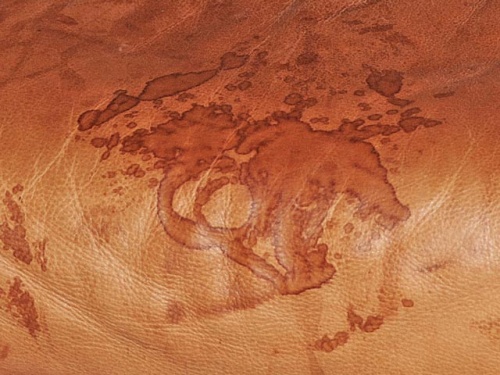

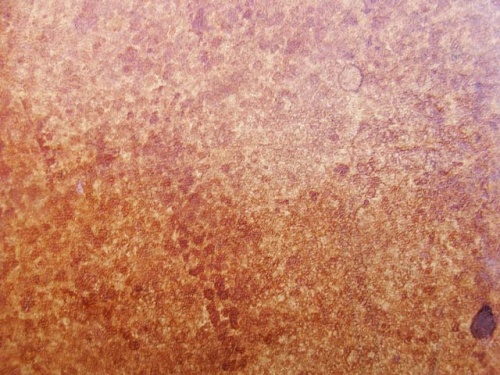

The first picture shows a drop of water on a pigmented cowhide. The drop does not penetrate the leather. On the other pictures the drop of water sinks into a porous aniline leather.

When water enters porous leather, the leather fibre can swell and it can change the surface and height structure. This is typical for aniline leather, which were not waterproofed during production.

The water drops have changed the surface. The edges of the water marks are swollen.

Waterproof leather

Waterproof leather is made highly water-repellent through tanning and re-greasing. Waterproof leather can contain up to 23% emulsified fats.

Video about the water sensitivity of leathers

Film about the sensitivity of smooth leather.

Additional information

![]() -> COLOURLOCK - WATERPROOF SPRAY FOR NUBUCK, SUEDE & FABRICS

-> COLOURLOCK - WATERPROOF SPRAY FOR NUBUCK, SUEDE & FABRICS

![]() -> In German: www.lederzentrum.de

-> In German: www.lederzentrum.de

![]() -> Rest of the world: partners worldwide

-> Rest of the world: partners worldwide

a kotori web solution

a kotori web solution