Liming - Leather Tanning

Liming is one of the main steps carried out during leather production in the tannery. The main purpose of liming is to separate the hair from the hides. Leather is used both with hair (for furs) and without hair. Most of the leather is de-haired in the tannery. Shoes, belts, car and furniture are produced without hairs on the leather.

Leather, where the hair remains on the leather skin.

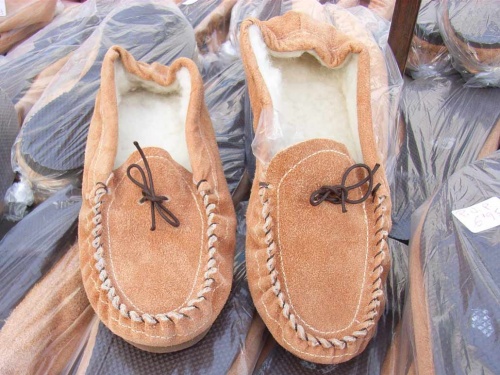

Most leather is processed without hair.

Tasks of liming

- Loosening the top skin and hair, so that it can be removed more easily.

- Loosening of meat and fat residues for removal.

- Removal of proteins that would affect the leather quality.

- Removal of fat in the skin.

- Swelling of the leather fibres.

- Open the skin structure, so that the fibres loosen and the tannins can be well connected.

Liming is done in Europe today with calcium hydroxide and sodium sulfide, which produces waste water that has to be treated in the company's own sewage treatment plants. Modern liming processes only destroy the hair root. This reduces the waste water load. The hair is filtered out, composted and used as fertilizer in agriculture.

Liming in the drum. - After liming the next working steps are fleshing and splitting.

In the past, liming was done with ashes and water.

Videos about the leather production

The leather production in a modern tannery.

| Process steps in the leather production |

|---|

| storage - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing - fatliquoring - retanning - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution