Difference between revisions of "Oils & fats in the leather industry"

m (→Fats in leather care and finish) |

|||

| Line 69: | Line 69: | ||

! bgcolor=#eeeeee | [[Leather production|Process steps in the leather production]] | ! bgcolor=#eeeeee | [[Leather production|Process steps in the leather production]] | ||

|- | |- | ||

| − | | bgcolor=#ffffff align=center | [[storage of leather|storage]] - [[soaking]] - [[Liming - Leather Tanning|liming]] - [[Fleshing - Making of leather|fleshing]] - [[Split leather|splitting]] - [[pickling]] - [[Tanning leather|tanning]] - [[neutralising]] - [[Drying leather|withering]] - [[Leather production#Sorting|sorting]] - [[shaving]] - [[Leather production#Dyeing (through colouring) and fatliquoring| | + | | bgcolor=#ffffff align=center | [[storage of leather|storage]] - [[soaking]] - [[Liming - Leather Tanning|liming]] - [[Fleshing - Making of leather|fleshing]] - [[Split leather|splitting]] - [[pickling]] - [[Tanning leather|tanning]] - [[neutralising]] - [[Drying leather|withering]] - [[Leather production#Sorting|sorting]] - [[shaving]] - [[Leather production#Dyeing (through colouring) and fatliquoring|dyeing (through colouring) and fatliquoring]] - [[Drying leather|drying]] - [[finish]] - [[softening]] - [[Leather quality|final check]] |

|} | |} | ||

</center> | </center> | ||

Revision as of 13:10, 5 February 2017

Contents

Oils, fats and waxes in the leather production

The use of greases, oils and waxes in the leather production process is important. They are used in production to influence certain properties (softness, waterproofing or appearance). Fats, oils and waxes are main components of leather care and are sometimes used directly during tanning also.

Fatliquoring (regreasing)

In the tanning process, the natural fats of the animal are removed from the rawhide as they are not preserved and become rancid. To obtain a soft and stable leather, it must be re-greased. Already at the origins of tanning, leather was therefore re-greased with milk, brain, egg yolk, vegetable oil or fish transe (also called "fish oil"). Fats were also used for fat tanning. A finished oiled leather has a fat content of up to 25%.

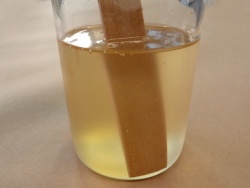

Fatliquoring involves reapplying of water-soluble oils to leather. This can be done in the tanning process or even after dry cleaning. Dry cleaning is a cleaning process in a solvent bath which strongly degreases the leather. The fatliquor makes the leather supple and stable and gives a handsome appearance to the "starved" look of degreased leather.

Oils and fats in leather affect the smell of leather. It is only one substance of many substances used when tanning which influences the smell of the finished leather. Fatliquors of good quality do not have an intrusive odour.

Raw materials for the fatliquoring agents

Sea animal oils: Fish oil

Land animal oils and fats: Claw oil, beef tallow, pig fat, bone fat

Vegetable oils and fats: Palm oil, sunflower oil, rapeseed oil, soybean oil, coconut fat, palm kernel fat, turkey red oil

Waxes: Carnauba wax, montan wax, wool grease

Synthetic fats: Paraffin oil, mineral oil, fatty alcohol, fatty acid ester

Fish oil - Claw oil

Fats in leather care and finish

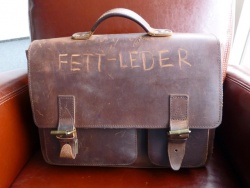

Leather is not only greased and oiled in the production to make it supple and soft. Fats and oils are also used as leather care to correct wear (in particular, shoe polish), or to waterproof leather, or to preserve old and dry leather by re-greasing and softening.

Oils, greases and waxes are also used in the finish. In case of pull up (greased leather - waxed leather - oiled leather), these substances are used to achieve certain effects in the surface. Pull-up leather usually has patina which increases with time.

Pull up leather - Waxed leather

Additional information

- Pull up leather - Greased leather - Waxed leather - Oiled leather

- Leather care

- Shoe care

- Tanning with fats and oils

Video about the leather production

The leather production in a modern tannery.

a kotori web solution

a kotori web solution