Difference between revisions of "Suede - Nubuck - Buckskin"

| Line 7: | Line 7: | ||

Nubuck and suede is [[Sanding leather|sanded]] leather with a more or less velvet-like surface. The advantage is a pleasantly warm and soft surface and a nice structure. | Nubuck and suede is [[Sanding leather|sanded]] leather with a more or less velvet-like surface. The advantage is a pleasantly warm and soft surface and a nice structure. | ||

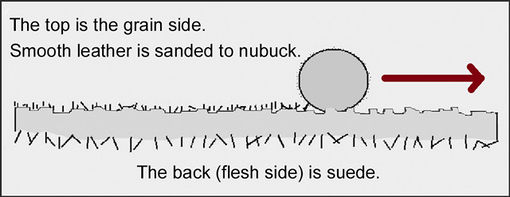

| − | On the [[Leather grain - Grain side|grain side]], rough sanded [[smooth leather]] is called nubuck. The surface of the reverse ([[flesh side]]) is called suede. Also the outwardly processed, uncoated back of a [[smooth leather]], [[Sheepskin - Lambskin|lambskin]] or [[cowhide]] is called suede. On nubuck, the velvety sanded leather | + | On the [[Leather grain - Grain side|grain side]], rough sanded [[smooth leather]] is called nubuck. The surface of the reverse ([[flesh side]]) is called suede. Also, the outwardly processed, uncoated back of a [[smooth leather]], [[Sheepskin - Lambskin|lambskin]] or [[cowhide]] is called suede. On nubuck, the velvety sanded leather fibres are very fine. The fibres of suede are significantly coarser. |

| Line 18: | Line 18: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''On nubuck, the sanded leather | + | ''On nubuck, the sanded leather fibres are very fine.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 39: | Line 39: | ||

==Buckskin== | ==Buckskin== | ||

| − | Buckskin was a traditional [[Types of leather|type of leather]] of the | + | Buckskin was a traditional [[Types of leather|type of leather]] of the Indians of North America. The [[Leather grain - Grain side|grain surface]] of [[Deerskin|deer]], [[Reindeer leather|reindeer]] and [[Elkskin leather|elk]] skins was scratched away and the skin was processed to suede. Buckskin was [[brain tanning|brain tanned]] or [[tanning leather|tanned]] with [[Tanning with fats and oils|fish oil]] or aldehyde or combinations of it. Some buckskin leathers get a [[finish]] on one of the sides. [[brain tanning|Brain tanned leather]] is usually smoked heavily to prevent it from rotting. Buckskin is used for [[leather shoes|shoes]], [[leather bag|bangs]] and [[leather clothing]]. |

| Line 51: | Line 51: | ||

==Nubuck== | ==Nubuck== | ||

| − | Nubuck is [[smooth leather]] [[Sanding leather|sanded]] rough on the [[Leather grain - Grain side|grain side]]. The | + | Nubuck is [[smooth leather]] [[Sanding leather|sanded]] rough on the [[Leather grain - Grain side|grain side]]. The roughening with an abrasive gives the leather a velvety surface. The leather is thus very [[Haptic evaluation of leather surfaces|soft]] and it has a good [[Breathability of leather|breathability]]. Rearly, the term "nubucked leather" is used for nubuck. |

The disadvantage of this surface is a markedly increased sensitivity to stains and soiling. The [[Colour fastness - Light fastness of leather|UV resistance]] is also significantly reduced and therefore tend to fade. Nubuck and suede also have a higher risk of [[Dye transfer from leather|dye transfer]]. This can be due to [[Sanding leather|sanding]] dust or excess [[leather colour|dyes]]. | The disadvantage of this surface is a markedly increased sensitivity to stains and soiling. The [[Colour fastness - Light fastness of leather|UV resistance]] is also significantly reduced and therefore tend to fade. Nubuck and suede also have a higher risk of [[Dye transfer from leather|dye transfer]]. This can be due to [[Sanding leather|sanding]] dust or excess [[leather colour|dyes]]. | ||

| Line 94: | Line 94: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Nubuck in the [[car leather#BMW|BMW Z1]] in the back and side flanks. - Nubuck roof sky in the [[car leather|BMW|BMW E28 M5]] from 1986.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 111: | Line 111: | ||

[[Embossed leather|Embossed]] nubuck is nubuck leather on which a [[leather colour|coloured]] embossing has been applied with a roller. In the area of the [[finish|colour application]] (the dark areas), the leather is then a pigmented [[smooth leather]] and in between (light areas) a normal nubuck leather. The [[Embossed leather|embossing]] is always darker than the nubuck leather. | [[Embossed leather|Embossed]] nubuck is nubuck leather on which a [[leather colour|coloured]] embossing has been applied with a roller. In the area of the [[finish|colour application]] (the dark areas), the leather is then a pigmented [[smooth leather]] and in between (light areas) a normal nubuck leather. The [[Embossed leather|embossing]] is always darker than the nubuck leather. | ||

| − | [[Embossed leather|Embossed]] nubuck was widely used in the 80s and 90s. In the meantime, this type of leather is rarely found. | + | [[Embossed leather|Embossed]] nubuck was widely used in the 80s and 90s. In the meantime, this type of leather is rarely found. Occasionally, embossed nubuck is used for [[leather clothing|clothing]] and [[leather shoes|shoes]]. For [[car leather|cars]], it has never been used. |

| Line 125: | Line 125: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''There are many different patterns. | + | ''There are many different patterns. Most typical is the [[Natural leather grain|natural grain optic]] of [[smooth leather]].''<br></p> |

<p> </p> | <p> </p> | ||

| Line 134: | Line 134: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Here, only the [[Natural leather grain|grain]] of a [[smooth leather]] was [[Embossed leather|embossed]] without | + | ''Here, only the [[Natural leather grain|grain]] of a [[smooth leather]] was [[Embossed leather|embossed]] without colouring into the nubuck.''<br></p> |

<p> </p> | <p> </p> | ||

| − | A new variant of embossing and nubucking is the [[Embossed leather|deep embossing]]. Therefore a [[finish|pigmented]] smooth leather is deep [[Embossed leather|embossed]]. Then, the protruding edges are abraded. The manufacturer points out, that the leather is not suitable for seat and wear surfaces. The edges wear too easily by use. | + | A new variant of embossing and nubucking is the [[Embossed leather|deep embossing]]. Therefore, a [[finish|pigmented]] smooth leather is deep [[Embossed leather|embossed]]. Then, the protruding edges are abraded. The manufacturer points out, that the leather is not suitable for seat and wear surfaces. The edges wear too easily by use. |

| Line 151: | Line 151: | ||

==Suede== | ==Suede== | ||

| − | Suede is the name of two types of leather. One is the [[ | + | Suede is the name of two types of leather. One is the [[split leather]] (double-sided velour surface. The second is the uncoated [[flesh side]] of a [[smooth leather]] (reverse). In contrast to the very velvety nubuck, the suede is significantly rougher. |

| Line 170: | Line 170: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Suede [[leather furniture|furniture]].''<br></p> |

<p> </p> | <p> </p> | ||

| − | The most common use of | + | The most common use of suede leather is the use of [[leather shoes|sneakers]] as well as [[Leather gloves|working gloves]]. In both cases, the protective function and the strong [[Breathability of leather|breathability]] of this type of leather is wished. Suede is very [[Porous leather|porous]], and sweat can therefore very well pass through. As hands and feet sweat very quickly, this advantage plays an important role. |

| Line 186: | Line 186: | ||

<p align=center> | <p align=center> | ||

| − | ''[[leather shoes|Sneakers]] often have surfaces made of suede. With [[Sheepskin - Lambskin|lambskin]] slippers, the | + | ''[[leather shoes|Sneakers]] often have surfaces made of suede. With [[Sheepskin - Lambskin|lambskin]] slippers, the velour side ([[flesh side]]) is processed on the outside.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 193: | Line 193: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Suede is often used for working gloves.''<br></p> |

<p> </p> | <p> </p> | ||

| − | When gluing leather on car parts, the [[flesh side]] leather | + | When gluing leather on car parts, the [[flesh side]] leather fibres are often pressed and glued down beforehand so that irregularities are not visible on the upper side later. The back is more even pre-treated like this. |

| Line 204: | Line 204: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''On the right the | + | ''On the right the velour fibres were glued down and [[Ironing leather|ironed]].''<br></p> |

<p> </p> | <p> </p> | ||

Revision as of 21:48, 9 February 2017

Contents

Nubuck & Suede

Nubuck and suede is sanded leather with a more or less velvet-like surface. The advantage is a pleasantly warm and soft surface and a nice structure.

On the grain side, rough sanded smooth leather is called nubuck. The surface of the reverse (flesh side) is called suede. Also, the outwardly processed, uncoated back of a smooth leather, lambskin or cowhide is called suede. On nubuck, the velvety sanded leather fibres are very fine. The fibres of suede are significantly coarser.

On nubuck, the sanded leather fibres are very fine.

Suede has significantly coarser leather fibres.

Nubuck leather is made by sanding rough the grain side.

Buckskin

Buckskin was a traditional type of leather of the Indians of North America. The grain surface of deer, reindeer and elk skins was scratched away and the skin was processed to suede. Buckskin was brain tanned or tanned with fish oil or aldehyde or combinations of it. Some buckskin leathers get a finish on one of the sides. Brain tanned leather is usually smoked heavily to prevent it from rotting. Buckskin is used for shoes, bangs and leather clothing.

Video about leather from different type of animals.

Nubuck

Nubuck is smooth leather sanded rough on the grain side. The roughening with an abrasive gives the leather a velvety surface. The leather is thus very soft and it has a good breathability. Rearly, the term "nubucked leather" is used for nubuck.

The disadvantage of this surface is a markedly increased sensitivity to stains and soiling. The UV resistance is also significantly reduced and therefore tend to fade. Nubuck and suede also have a higher risk of dye transfer. This can be due to sanding dust or excess dyes.

Nubuck has a very fine pile, recognizable when wiping over.

Nubuck can be waterproofed. In case of older leathers, the waterproofing properties decreases and drops start penetrating the surface.

Nubuck leather is mainly made from cowhides and calfskins. But also goat, lamb or deer skins are processed to nubuck. Nubuck is used for furniture, handbags, clothing and shoes. Only rarely for cars like the Z1 from BMW or the Maybach from Mercedes.

Nubuck leather furniture.

Only slightly sanded leather (slightly nubucked) from www.leder-fiedler.de and furniture of www.marquardt-produktion.de.

Nubuck in the BMW Z1 in the back and side flanks. - Nubuck roof sky in the BMW|BMW E28 M5 from 1986.

Nubuck leather glove compartment at the Mercedes Maybach. - Nubuck on a bike saddle.

The term "nubuck" might come from "buckskin". It is assumed that "new buck" coming from "buckskin" was shortened to "nubuck".

Embossed nubuck

Embossed nubuck is nubuck leather on which a coloured embossing has been applied with a roller. In the area of the colour application (the dark areas), the leather is then a pigmented smooth leather and in between (light areas) a normal nubuck leather. The embossing is always darker than the nubuck leather.

Embossed nubuck was widely used in the 80s and 90s. In the meantime, this type of leather is rarely found. Occasionally, embossed nubuck is used for clothing and shoes. For cars, it has never been used.

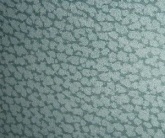

There are many different patterns. Most typical is the natural grain optic of smooth leather.

Here, only the grain of a smooth leather was embossed without colouring into the nubuck.

A new variant of embossing and nubucking is the deep embossing. Therefore, a pigmented smooth leather is deep embossed. Then, the protruding edges are abraded. The manufacturer points out, that the leather is not suitable for seat and wear surfaces. The edges wear too easily by use.

Optics of the nubucked deep embossing.

Suede

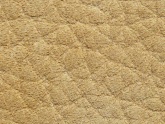

Suede is the name of two types of leather. One is the split leather (double-sided velour surface. The second is the uncoated flesh side of a smooth leather (reverse). In contrast to the very velvety nubuck, the suede is significantly rougher.

Close-up of suede.

Suede furniture.

The most common use of suede leather is the use of sneakers as well as working gloves. In both cases, the protective function and the strong breathability of this type of leather is wished. Suede is very porous, and sweat can therefore very well pass through. As hands and feet sweat very quickly, this advantage plays an important role.

Sneakers often have surfaces made of suede. With lambskin slippers, the velour side (flesh side) is processed on the outside.

Suede is often used for working gloves.

When gluing leather on car parts, the flesh side leather fibres are often pressed and glued down beforehand so that irregularities are not visible on the upper side later. The back is more even pre-treated like this.

On the right the velour fibres were glued down and ironed.

Cleaning and care instructions

![]() -> COLOURLOCK - CLEANING AND CARE OF NUBUCK AND SUEDE FURNITURE

-> COLOURLOCK - CLEANING AND CARE OF NUBUCK AND SUEDE FURNITURE

![]() -> COLOURLOCK - CLEANING AND CARE OF NUBUCK AND SUEDE SHOES

-> COLOURLOCK - CLEANING AND CARE OF NUBUCK AND SUEDE SHOES

![]() -> In German: http://www.lederzentrum.de/tip/index.html www.lederzentrum.de]

-> In German: http://www.lederzentrum.de/tip/index.html www.lederzentrum.de]

![]() -> Rest of the world: partners worldwide

-> Rest of the world: partners worldwide

Videos

The cleaning of suede shoes.

Additional information

- Buckskin

- Split leather

- Coated split leather

- Nubucato

- Semi-nubuck

- Chamois leather - Wash leather

- Types of leather

a kotori web solution

a kotori web solution