Split leather

Contents

- 1 What is split leather?

- 2 Video about the coating of split leather

- 3 Applications for split leather

- 4 The splitting of leather

- 5 Processed split leather

- 6 Coated split leather - Laminated split leather

- 7 Embossed split leather

- 8 Typical split leather damages

- 9 Additional information

- 10 Video about the leather production

What is split leather?

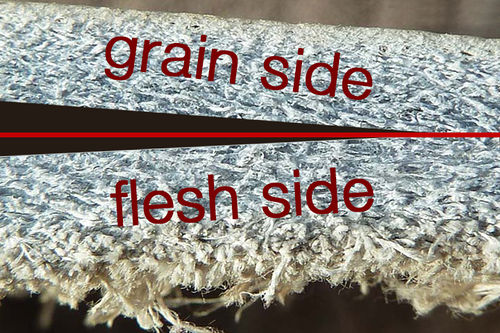

If a skin is divided into several layers over the entire surface, this process is called "splitting". Thicker leather, mostly cow leather, which is 5 to 10 millimeters thick, is split. The obtained layers are designated as grain split or top-grain split and flesh split. Somtimes the leather is thick enough for a middle split. The split, separated from the grain split, is also called drop split. The drop-split leather is rough on both sides like the back of a leather.

When adjusting the splitting machine, the tanner must consider that the thickness of the skin is higher at this work step due to the water content of the wet skin. The water content of a wet skin is three times heavier than the dry weight of leather. Soaked with water, leather is therefore thicker. The tanner has to consider this difference in thickness when adjusting the splitting machine so that the desired leather thickness comes out when the leather is dry.

The hide is split. Above is then the grain split and below the flesh split. Outside the tannery, only the flesh split is considered as "split leather"

The grain split is considered more valuable. The fiber structure is substantially denser in the upper layer of the grain side and is thus tear-resistant. The grain split is referred to smooth leather when ready tanned.

After leaving the tannery, the term "grain split" is no longer used. The leather dealer then uses terms such as "smooth leather", "aniline leather", "napa", depending on the leather type. The term "split" no longer appears in connection with the grain side. The drop split with the two rough sides is then no longer referred to as a "flesh split", but as a "split leather", "split" or "suede". In order to make the leathers more intelligible to the layman, this is an important separation of the choice of words in tanneries and in public. This makes it clear that the term "split" is always referring to the less stable lower layer of the hide.

As the quality of a split leather is lower then the top grain leather, ther are rules about the use of the terms. But the rules are different from country to country. Some countries don`t allow to label split leather as "leather". Some allow to call it leather but only when further details make clear, that it's a split leather.

It is indisputable that a split leather does not have the same quality features as a top-grain leather. If a split leather is coated in such a way that it looks like a grain leather, the end user cannot recognize the quality. The leather is then like a veneered wood of lower quality. The upper layer with smooth leather optic is then no leather, but a coating and the grain is created by an embossing.

Therefore, only labeling requirements are fair and aceptable from the end-user viewpoint, if split leather explicitly and clearly must be pointed out.

Video about the coating of split leather

Video about the production of plastic coated split leather.

Applications for split leather

Leather clothing

In the clothing sector porc split or goat suede are very common. Pig leather is generally somewhat stiffer and not as tear-resistant as a goat suede. Therefore, pig leather is mostly used for low price leather clothing.

Leather shoes

In the shoe sector, split leather is widely used for sneakers sports shoes because of its breathability.

Suede is very common for shoes.

Furniture leather

In the lower price segment of leather furniture, on contact surfaces (backs, seats, armrests) sometimes better leather is processed and for the rest (outsides, back of the furniture) coated split or imitation leather is used. In the very low price segment, somtimes the complete furniture is covered with coated split. Usually such leather is only declared with "real leather" and similar terms. Such furniture then has a reduced life expectancy and in some countries, if this happens to early (warranty period), the furniture can be successfully claimed.

For this reason, you should always ask what materials have been processed. Unfortunately, the declarations are very often wrong, especially when buying online.

Car leather

Even the vehicle manufacturers up to the higher price classes increasingly use coated or embossed split leather for the less stressed areas (door linings, headrests) without corresponding declaration. The buyer acquires in good faith a high-quality "leather interior" or "full leather trim" at a high surcharge.

Although no manufacturer infomes about processed split leather in their vehicles, companies specializing in split leather indicate that over 10 million steering wheels have been covered with split leather. Door linings, seat parts and other areas in the vehicle are also covered with embossed split leather.

Complete cow hides are over 5 square meters in size. The usuable area of the split leather for the automotive sector is the 1.5 square meter butt. This is the best part of the hide.

Split leather does not have the tear strength of a top grain leather. It is usually impossible to tear a top grain leather with hands in contrast to split leather.

An indication of the used material would be desirable in order for consumers to be able to distinguish the split leather from the higher quality leather.

In principle, split leather is also not a bad leather, if it is declared correctly and is produced or used for a Long-lasting use. 99,9% of the customers believe that the smooth leather steering wheel or door trim is the grain side of the leather, but in reality it is a coated split leather. Only a clear declaration would convey to the end customer in a comprehensible manner whether he had paid for a high-quality or cheap leather.

Therefore even with the high-priced brands should be asked, whether split leather was processed or higher-quality top grain leather. It can be confirmed in the purchase contract.

The splitting of leather

Image 1: Cow leather is at least split into two layers. - Image 2: Top grain leather with hair side.

The drop split is rough on both sides. After leaving the tannery it is called "suede" or "split".

Image 1: Splitting machine in the tannery. - Image 2: Thickness control measurement.

Processed split leather

There are many areas where split leather is the right choice. For shoes, clothing or bags, split leather is traditionally processed without problems. It is usually the furniture sector, where split leather is sold with a smooth leather finish, which leads to disappointments among the customers.

Image 1: Split leather (suede) can be found in nearly every household in the shoe shelf as a sneaker. - Image 2: A suede leather chair from the 50s.

Coated split leather - Laminated split leather

Damit Spaltleder eine pflegeleichte Oberfläche bekommt, wird es manchmal beschichtet. Insbesondere im unteren Preissegment wird der Kunde aber nicht darauf hingewiesen, dass er nicht das hochwertige Narbenleder hat, sondern ein preiswertes Spaltleder mit einer Folienbeschichtung. Leider sind die Reklamationsquoten bei den preiswerten, beschichteten Spaltledern sehr hoch und die Lebensdauer deutlich geringer als bei den Narbenledern. Insbesondere die in der Vergangenheit fälschlicher weise mit dem Begriffe PU-Leder deklarierten Materialien hatten oft Qualitätsprobleme.

Die Pflichtdeklaration ist "Beschichtetes Leder", wenn die Schichtstärke der Beschichtung größer als 0,15 Millimeter ist.

Typische Optik beschichteter Spaltleder.

Eine ab 2011 neu erschienene Variante des beschichteten Spaltleders ist ein mit einem Textilgewebe beschichtetes Spaltleder. Laut Hersteller ist dann die Proportion 89% Spaltleder und 11% Fremdmaterial der Beschichtung. Bisher ist dieses Material unter den Namen Rodeo, Pilotenleder, und Tasan angeboten worden. Da das Material noch sehr jung ist, kann man außer der für Textilien ungewöhnlich starken Ausbleichung bei einem Fall beim Tasan noch keine Aussagen treffen. Die richtige Deklaration für dieses Material lautet "Mit einer Textilschicht beschichtetes Spaltleder". Als "Echt Leder" darf dieses Material nicht angeboten werden. Es wäre eine Falschdeklaration und ein Reklamationsgrund in den ersten zwei Jahren nach dem Kauf.

Auf der Oberfläche ist eine textile Gewebeschicht aufgeklebt - Pilotenleder und Tasan.

Veloursleder mit einer textilen Beschichtung - RODEO

Es gibt aber noch mehr Varianten. Spaltleder kann auch von der Rückseite zu Stabilisierung mit Gewebe kaschiert werden. Von oben kann es dann beschichtet und geprägt werden.

Beschichtetes und geprägtes Spaltleder mit einer Testilkaschierung

Embossed split leather

Als "geprägte Spaltleder" werden Spaltleder bezeichnet, deren Velouroberfläche mit einer Farbschicht überzogen worden sind und geprägt wurden. Diese Spaltleder sehen dann aus wie ein normales Narbenleder. Die Qualität ist aber nicht so gut, weil das Fasergefüge von Spaltledern i.d.R. nicht so hoch ist, wie das von Narbenledern. Es reißt leichter ein.

Geprägtes Spaltleder und geschiffenes und geprägtes Narbenleder sind nicht ohne Weiteres unterscheidbar.

Eindeutig geprägte Spaltleder. Nach Anlösen der Farbschicht kommt Velours zutage.

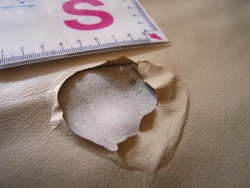

Typical split leather damages

Spaltleder sind anfälliger für Schäden als Narbenleder. Insbesondere im unteren Preissegment gibt es oft Probleme. Da löst sich die Beschichtung, das Leder reißt ein oder wird im Bereich von Haut- und Haarkontakt klebrig und löst sich auf. Insbesondere die fälschlicherweise als PU-Leder beworbenen Materialien waren davon betroffen.

Billige, beschichtete Spaltleder neigen oft zur Ablösung der Folie oder Farbschicht.

Abfärbungen von Leder und Farbablösungen auf Leder

Spaltleder reißen immer sehr faserig ein und sind auch deutlich anfälliger für Risse als narbenseitig verarbeitete Leder.

Bei beschädigten "Narbenledern" ist die Oberfläche in der ersten Phase des Verschleißes der Farbschicht glatt.

Additional information

Video about the leather production

The leather production in a modern tannery.

| Process steps in the leather production |

|---|

| storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing (through colouring) and fatliquoring - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution