Difference between revisions of "Chrome tanned"

| Line 6: | Line 6: | ||

==History of chrome tanning== | ==History of chrome tanning== | ||

Until the 19th century, there was little progress in the [[tanning|tanning process]]. While there was some use of [[Tawing with alum|alum (aluminium) salts]] and [[tanning#Tanning methods|other tanning methods]], most tanning was done by the [[vegetable-tanned leather|vegetable tanning]] process. In 1858, chrome tanning was invented by the German technologist F. Knapp & Cavalin, a Swede. However, it was an American chemist by the name of Augustus Schultz who first patented the chrome tanning process. | Until the 19th century, there was little progress in the [[tanning|tanning process]]. While there was some use of [[Tawing with alum|alum (aluminium) salts]] and [[tanning#Tanning methods|other tanning methods]], most tanning was done by the [[vegetable-tanned leather|vegetable tanning]] process. In 1858, chrome tanning was invented by the German technologist F. Knapp & Cavalin, a Swede. However, it was an American chemist by the name of Augustus Schultz who first patented the chrome tanning process. | ||

| + | |||

| + | |||

| + | <p align=center> | ||

| + | [[bild:Ball-Chrome-tanning-1920.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

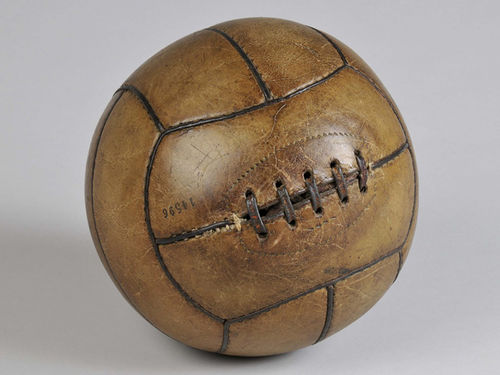

| + | ''Beginnings of chrome tanning: Ball of chrome-tanned cow leather from before 1920 ([[Leather museum|© German Ledermuseum, C. Perl-Appl]]).''<br></p> | ||

| + | <p> </p> | ||

In the following decades, chrome tanning became the most common and dominant kind of [[tanning]]. Chrome tanning process meant leathers could be tanned in a matter of days in comparison to vegetable tanning. The reduced time was a main decisive factor to Chrome tanning becoming one of the main tanning process. The discovery of chrome tanning coincided with the discovery of [[Oils & fats in the leather industry#fatliquoring (regreasing)|fatliquoring (regreasing)]] process and also the development of [[leather colour|synthetic dyes]]. This combination of new techniques and products to tan leather led to it becoming the preferred tanning method. Chromium salts belong to the group of [[Mineral tanning|mineral tannins]]. | In the following decades, chrome tanning became the most common and dominant kind of [[tanning]]. Chrome tanning process meant leathers could be tanned in a matter of days in comparison to vegetable tanning. The reduced time was a main decisive factor to Chrome tanning becoming one of the main tanning process. The discovery of chrome tanning coincided with the discovery of [[Oils & fats in the leather industry#fatliquoring (regreasing)|fatliquoring (regreasing)]] process and also the development of [[leather colour|synthetic dyes]]. This combination of new techniques and products to tan leather led to it becoming the preferred tanning method. Chromium salts belong to the group of [[Mineral tanning|mineral tannins]]. | ||

Revision as of 16:51, 20 November 2016

Contents

History of chrome tanning

Until the 19th century, there was little progress in the tanning process. While there was some use of alum (aluminium) salts and other tanning methods, most tanning was done by the vegetable tanning process. In 1858, chrome tanning was invented by the German technologist F. Knapp & Cavalin, a Swede. However, it was an American chemist by the name of Augustus Schultz who first patented the chrome tanning process.

Beginnings of chrome tanning: Ball of chrome-tanned cow leather from before 1920 (© German Ledermuseum, C. Perl-Appl).

In the following decades, chrome tanning became the most common and dominant kind of tanning. Chrome tanning process meant leathers could be tanned in a matter of days in comparison to vegetable tanning. The reduced time was a main decisive factor to Chrome tanning becoming one of the main tanning process. The discovery of chrome tanning coincided with the discovery of fatliquoring (regreasing) process and also the development of synthetic dyes. This combination of new techniques and products to tan leather led to it becoming the preferred tanning method. Chromium salts belong to the group of mineral tannins.

Immediately after tanning, the leather is still wet and gets a blue tinge, hence it is also referred to as wet blue.

Chromium (III) oxide in powder form.

The global importance of chrome tanning

Chrome tanning with chromium (III) salts accounts for around 85 percent of global leather production (as per 2014). 95% of shoe upper leather, 70% of leather upholstery (but decreasing in favour of FOC-leather) and almost 100% of clothing leather are chrome tanned.

Unlike vegetable tanned leather, it has twice the tensile strength, while it has a lighter weight because the chromium salts used for tanning do not fill the skin. The tannin makes up only 4% (with newer leathers even only about 1.5%) of the leather weight, while vegetable-tanned leather has a tannin content of about 20 percent.

Chrome-tanned leather is easier to hydrophobized as with other tanning alternatives and the leather can easier be softened. The tanning process is faster and less tanning chemistry is needed compared to vegetable-tanned leather.

Cost saving: Freshly tanned wet blue with its characteristic bluish tint is globally transportable and can be stored well. This facilitates unlimited international sales and global processing.

Chrome tanning in the tanning drum.

| Area | Chrome-tanned leather in % | tendency |

|---|---|---|

| Shoe upper leather | 95 | No change |

| Furniture leather | 70 | Decrease in favour FOC-leather) |

| Car leather | 50 | Decrease in favour FOC-leather) |

| Garment leather | 100 | No change |

| [[Leather handbags|Bags, belts, accessories | 60 | No change |

| Sole leather | - | No change |

Source: Journal leather & skins market - Leder & Häute Markt 3/2008, page 46.

"Wet blue" = damp, grey-bluish leather dyed right after chrome tanning by chromium.

As a tanning agent, almost always, 33% basic chromium sulphate is used with 26% of chromium (III) oxide content. Annually 480000 tonnes are produced in chrome tanning worldwide, which is about 125000 tonnes of chromium (III) oxide. The use of chromium (III) salts is considered harmless to health and does not give rise to any difficulties in the vast majority of people, despite intensive skin contact in footwear or apparel. Drinking water is allowed to contain 50 micrograms (chromium III) per litre.

Major suppliers of chromium are South Africa with 38%, India 20%, Kazakhstan 15%, Turkey with 7%, Russia, Brazil and Zimbabwe each with 3% and Finland with 2%.

Chrome-free leather - FOC = Free of Chrome

FOC (free of chrome, chrome-free) labelled leather is tanned with tannins free of chromium (III). They are now increasingly used in automotive upholstery and furniture upholstery. The leather seats of Audi and Porsche are always free of chrome.

The production of FOC-leather is more complex than that of the chrome-tanned leather. For example, in the tanning process, an exact temperature must be observed to successfully tan. FOC leather is mostly produced in developed countries.

Frequently chromium-free leather is advertised with descriptions such as "without chromium and pollutants". This can give the impression that chrome tanning is harmful whereas tanning with chromium III is absolutely harmless. Many people associate "chrome" to be toxic or may have read in the press about the exceedances of chromium VI. Marketing ideas for FOC leather usually exaggerate these fears.

FOM (free of metal) is the name for leather that has been tanned completely without the use of metals and their compounds (as aluminium, iron or titanium).

Currently, the chromium tanning is extremely dominant. Alternative tanning methods cannot replace this kind of tanning mainly due to costs and technical considerations. Many vegetable tanning agents occur naturally and there is simply not enough quantity of these agents readily available yearly to satisfy the demand for leather production worldwide.

Chrome VI - Chromium VI

Chromium (VI) is harmful and can occur under improper tanning conditions in the leather. However, this aspect is now well researched and can be avoided.

Chrome tanning - Ecology

Environmental considerations with respect to chrome tanning are also relevant. The chromium-containing waste water and waste materials, must be recycled to recover valuable materials. Modern tanneries manage to bind up to 97% of the chromium used in the leather fibre, to keep the waste water load low and to save costs.

Correct disposal of chrome-tanned leathers is important. For example, leather seats in scrapped cars require appropriate handling because combustion of chrome-tanned leather can produce harmful chromium (VI). Formation behaviour of chromium (VI) under conditions of high heat (bright sunlight on black car upholstery or dashboard leather) should also be reviewed regularly.

Additional information

- Vegetable-tanned leather

- Mineral tanning

- Synthetic tanned

- Chamois leather

- Tawing with alum

- Brain tanning

Video about leather production

The leather production in a modern tannery.

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution