Difference between revisions of "Leather quality"

| (59 intermediate revisions by one user not shown) | |||

| Line 4: | Line 4: | ||

| − | == | + | ==What is leather quality?== |

| − | + | It is easy to identify the vast differences in skin quality that exist from [[Exotic leather|one species to another]]. [[Leather]] is not always equal in quality. Gender, age, nutrition, feeding and general care all affect an animal's skin. Also there may be differences [[Parts of the hide|within a skin of one animal]]. Below we explain how some of these factors can affect skin quality. | |

Differences in quality of [[Cow leather|cow leather]] (but also applies to other [[Exotic leather|species]]): | Differences in quality of [[Cow leather|cow leather]] (but also applies to other [[Exotic leather|species]]): | ||

| − | * '''Age''': The quality of hides from older animals is generally | + | * '''Age''': The quality of hides from older animals is generally poorer than that of younger animals. |

| − | * '''Gender''': | + | * '''Gender''': Female hides have a denser fibre structure and a finer [[Grain side|grain structure]]. |

| − | * '''Gender specific activities''': The more often a male animal | + | * '''Gender specific activities''': The stability of the skin's fibre structure deteriorates the more often a male animal mates and, for a female, the number of times she gives birth. Castrated oxen tend to have a finer skin structure. |

| − | * '''Nutrition''': Fresh | + | * '''Nutrition''': Fresh forage promotes better quality skin. |

| − | * '''Animal | + | * '''Animal husbandry''': The skin of animals kept on open pastures has a superior texture. |

| − | * '''Climate''': A harsh and cold climate | + | * '''Climate''': A harsh and cold climate promotes a good skin quality. A rule of thumb is that hides from above the 37th parallel are of better quality. |

| − | [[Leather]] is used for many different applications. As [[Car leather|car leather]], for [[Leather shoes|shoes]], for [[Leather straps|leather straps]] and [[Leather belt|belts]], for [[Leather suits|leather suits]] or [[Haptic evaluation of leather surfaces|buttery soft]] [[Leather gloves|leather gloves]]. | + | [[Leather]] is used for many different applications. As [[Car leather|car leather]], for [[Leather shoes|shoes]], for [[Leather straps|leather straps]] and [[Leather belt|belts]], for [[Leather suits|leather suits]] or [[Haptic evaluation of leather surfaces|buttery soft]] [[Leather gloves|leather gloves]]. Diverse demands are placed on leather, depending on its use. [[Leather furniture|Furniture leather]] should be easy to [[Leather care|maintain]], while being [[Haptic evaluation of leather surfaces|soft and warm]]. [[Leather shoes|Shoe leather]] should be robust, [[Waterproofing leather|waterproofed]], soft, heat-retaining and [[Breathability of leather|breathable]]. [[Car leather|Car leather]] should be easy to [[Leather care|maintain]] and should be impervious to [[shrunken leather - leather shrinkage|heat]], cold and [[Leather damages|wear]]. |

| − | + | However it's used, leather should be durable and easy to [[Leather cleaner|clean]]. It should not tear, [[Colour fastness - Light fastness of leather|bleach]], [[Leather smell|smell unpleasant]] or contain pollutants. These are the essential "leather qualities" or "leather properties". | |

| Line 29: | Line 29: | ||

| − | + | However, leather can't be [[Haptic evaluation of leather surfaces|soft]], robust and easy to [[Leather care|clean and maintain]] all at the same time. Neither can it be paper thin and soft and also tear-proof. Optical influences such as [[Embossed leather|embossing]] or the [[Gloss of leather|degree of gloss]] also influence the parameters and can help or hinder the fulfillment of other parameters. | |

| − | In particular, the sensitivity of especially high quality leather | + | The art of tanning determines the correct coordination of all wishes and the fulfillment of necessary parameters. Over many work steps in [[leather production]], a suitable end result is worked towards by [[Tanner|tanners]], which can then be reproduced as best as possible for the customer. Depending on the [[types of leather|type of leather]], these challenges are enormous and require a lot of experience with more difficult types of leather such as [[aniline leather|open-pored smooth leather]]. |

| − | + | ||

| + | In particular, the sensitivity of especially high quality leather, such as the soft [[Aniline leather|aniline leather]] of a luxury [[Leather clothing|leather jacket]], of [[Exotic leather|exotic leather]] or of an expensive set of [[Leather furniture|furniture]] is often misjudged. | ||

| + | Because the object was so expensive customers therefore expect that it would be very easy to [[Leather cleaner|clean]] and [[Leather care|maintain]] the leather. But quite the opposite is true. Valuable leathers are as sensitive as silk. With regular use the beauty diminishes rapidly, while incorrect cleaning can even ruin the material. | ||

| Line 42: | Line 44: | ||

<p> </p> | <p> </p> | ||

| − | + | [[Car leather|Car leather]] is considered to be particularly robust. Most of the vehicle manufacturers require more than 40 quality criteria that must be fulfilled. Stringent wear tests must be passed. It must be resistant to suntan lotion and bug spray. Many chemicals are not allowed to be used and the [[Leather emission|leather emission]] level is tested. As a result, the leather is extremely durable, but no longer soft and warm to the touch. | |

| − | The [[Tanner|tanner]] and the producer of a leather object therefore should establish | + | The [[Tanner|tanner]] and the producer of a leather object therefore should establish their own, verifiable quality parameters, depending on the desired properties of leather. These parameters should take into account the [[Exotic leather|animal species]] and the [[Rawhide|rawhide]]. Differences in the quality of the [[Parts of the hide|individual sections of a skin]], including the possibility of [[Natural markings on leather|skin damage]] when [[Leather cutting|cutting]], must also be considered. Only a limited quantity of skins can be worked upon at any given time during the [[Tanning leather|manufacturing process of leather]] and all of them do not behave the same in each run. Often the [[Tanner|tanner]] will need to make minor changes during the process, which can lead to deviations from [[Leather batch|one batch to another]]. Differences can be detected depending on the quality control limits set. |

| − | + | Apart from the [[Tanning leather|production quality,]] the longevity of leather depends on certain other factors too. An important element for long-lasting pleasure of a a leather object is the handling of it. If leather is regularly [[Leather cleaner|cleaned]] and [[Leather care|maintained]] and not excessively overused and if the [[Basic rules when dealing with leather|basic rules in dealing with leather]] are respected, you will prolong the enjoyment of this durable and robust material. | |

==Leather testing - leather properties== | ==Leather testing - leather properties== | ||

| − | + | There are many different methods for testing and evaluating leather properties. For a layman, only rough and basic testing options are available when purchasing a good and beautiful leather item. Some of the criteria can be checked directly as an end customer, but when certain criteria cannot be tested, don't be afraid to ask the vendor the right questions. Below we list some basic checks that can be carried out. | |

| − | * '''Look of the leather''': A beautiful leather looks very natural and | + | * '''Look of the leather''': A beautiful top quality leather looks very natural and does not contain [[Natural markings on leather|markings]] on the surface. |

| − | * '''[[ | + | * '''[[Grain side|Leather grain texture]]''': The grain texture should look good and be as natural as possible. An [[Embossed leather|embossed grain pattern]] is very uniform, which does not correspond to the natural grain of a skin and embossed leather often feels less natural. |

| − | * '''[[Haptic evaluation of leather surfaces|Softness of the leather]]''': Generally, leather should be | + | * '''[[Haptic evaluation of leather surfaces|Softness of the leather]]''': Generally, leather should be soft to the touch and have a natural feel. But [[Leather shoes|leather shoes]] or [[Leather belt|leather belts]] require a certain strength. |

| − | * '''[[Haptic evaluation of leather surfaces]]''': | + | * '''[[Haptic evaluation of leather surfaces]]''': Leather should feel good, whether it's soft, blunt or smooth. The more beautiful leather feels, the better its quality. |

| − | * '''The [[Finish|leather finish]]''': To protect the leather, it is often useful to apply a [[Finish|binder based finish]] | + | * '''The [[Finish|leather finish]]''': To protect the leather, it is often useful to apply a [[Finish|binder-based finish]] to the surface. The more layers of leather paint are applied, the more unnatural it feels. If the grain texture is[[Sanding leather|sanded]] before the finish, the leather feels even more unnatural. So too does [[Coated leather - Laminated leather|film-coated leather]], usually considered to be inferior to natural leather and therefore relatively inexpensive. On the other hand, the effect is an accepted feature of [[Patent leather|patent leather]]. |

| − | * '''[[Breathability of leather]]''': An advantage of leather over alternative materials is | + | * '''[[Breathability of leather]]''': An advantage of leather over alternative materials is its breathability. But the more a leather is coated with leather colour or a film, the lower the breathability. |

| − | * '''Tear strength and stability of the leather''': Good leather is stable and resistant to tearing, | + | * '''Tear strength and stability of the leather''': Good leather is stable and resistant to tearing, wheareas [[Suede|suede]], [[Nubuck|nubuck]] or extremely soft [[Lamb leather|lambskin]] will not have the same stability as, for example, a [[Leather belt|belt leather]]. But within the [[Types of leather|types of leather]] very different qualities exist. So, an inferior quality leather within the same type of leather will always tear more easily than that of a higher quality. Also [[Sanding leather|sanded leather]] is usually less stable than [[Full grain leather|full-grain leather]]. |

| + | |||

| + | |||

| + | <p align=center> | ||

| + | <flashow>//www.youtube.com/v/gjjwzByy1eY&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow> </p> | ||

| + | <p align=center> | ||

| + | ''The causes of [[leather damages|damages]] of a leather couch.''<br></p> | ||

==Criteria of quality leather== | ==Criteria of quality leather== | ||

| − | To determine whether a leather corresponds to the desired quality requirements, it passes through a series of testing processes. | + | To determine whether a leather corresponds to the desired quality requirements, it passes through a series of testing processes. Extremely high and strict standards are set, particularly in the [[Car leather|automotive industry]]. Minimum qualities are set and controlled also for [[Leather furniture|furniture]], [[Leather shoes|shoes]] and [[Leather clothing|garment leather]]. In addition, there are statutory testing regulations for harmful substances, which is also a sign of quality. |

<p align=center> | <p align=center> | ||

| − | [[bild: | + | [[bild:Qualitätsprüfung.jpg|500px]] |

| − | [[bild: | + | </p> |

| − | [[bild:Lichtalterung-01.jpg| | + | <p align=center> |

| + | [[bild:Reibtest-02.jpg|250px]] | ||

| + | [[bild:Lichtalterung-01.jpg|250px]] | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''In the [[Tanning|manufacturing of leather]] the leather quality is constantly checked | + | ''In the [[Tanning leather|manufacturing of leather]], the leather quality is constantly checked using all senses and with test equipment.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 81: | Line 91: | ||

Test criteria for the leather quality include (and is regulated in many national and international standards): | Test criteria for the leather quality include (and is regulated in many national and international standards): | ||

| − | * '''[[Breathability of leather|Breathability]]''': The ability to absorb sweat | + | * '''[[Breathability of leather|Breathability]]''': The ability to absorb sweat through to the opposite side. |

| − | * '''Weight''': Important e.g. for [[Aircraft leather|aircraft leather]], because it should weigh as | + | * '''Weight''': Important e.g. for [[Aircraft leather|aircraft leather]], because it should weigh as little as possible to reduce fuel costs. |

* '''[[Thickness of leather]]''': The thickness has an influence on the stability of leather. | * '''[[Thickness of leather]]''': The thickness has an influence on the stability of leather. | ||

| − | * '''[[Tensile | + | * '''[[Tensile strength - Tear strength]]''': If the leather is drawn (for example, more than 200 N per 5 cm). |

* '''Tear force''': Leather should not easily tear further (for example, desirable: more than 20 N). | * '''Tear force''': Leather should not easily tear further (for example, desirable: more than 20 N). | ||

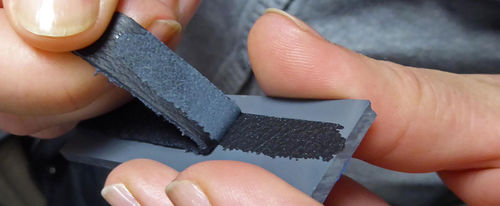

| − | * '''[[ | + | * '''[[Colour separation of leather|Adhesiveness]] of the [[Finish|finish]]''': The colour layers on the surface should not come off (for example, desirable: more than 25 N per 5 cm). |

| − | * '''Flammability and fire retardancy of leather''': Important for [[Aircraft leather|aircraft]], nursing homes, public buildings etc | + | |

| + | <p align=center> | ||

| + | [[bild:Leather-finish-test-01.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Test of the adhesiveness of the [[finish]].''<br></p> | ||

| + | <p> </p> | ||

| + | |||

| + | * '''Flammability and fire retardancy of leather''': Important for [[Aircraft leather|aircraft]], nursing homes, public buildings etc. | ||

| Line 100: | Line 118: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Flame-retardant leather.''<br></p> | + | ''[[Flammability and fire retardancy of leather|Flame-retardant]] leather.''<br></p> |

| + | <p> </p> | ||

| + | |||

| + | <p align=center> | ||

| + | [[bild:Flammability -Leather-01.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Devices for testing the [[Flammability and fire retardancy of leather|fire protection properties]].''<br></p> | ||

<p> </p> | <p> </p> | ||

| Line 107: | Line 132: | ||

* '''[[Colour fastness - Light fastness of leather|Light fastness]]''': Leather should not fade. | * '''[[Colour fastness - Light fastness of leather|Light fastness]]''': Leather should not fade. | ||

| − | * '''Flexibility''': Desirable: robustness in more than 100,000 cycles. Leather should be extensible, but not [[Dents | + | * '''Flexibility''': Desirable: robustness in more than 100,000 cycles. Leather should be extensible, but not [[Dents - Over stretching - Sagging in leather|baggy]]. |

| − | * '''[[Buckling | + | * '''[[Leather flexometer test|Buckling behaviour]]''': Leather should not break in folds. Desirable: 30,000 folds without damage. |

* '''[[Waterproofing leather|Water permeability]]''': Leather should be waterproof. | * '''[[Waterproofing leather|Water permeability]]''': Leather should be waterproof. | ||

| − | |||

| − | + | <p align=center> | |

| + | [[bild:Water-repellent-leather-01.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Laboratory test of the water-repellent properties of a [[nubuck]] leather.''<br></p> | ||

| + | <p> </p> | ||

| − | * ''' | + | * '''Acid and alkali resistance''': The leather surface should be resistant to chemicals as much as possible. |

| − | * ''' | + | * '''[[Hydrolysis resistance]]''': Leather should not decay as a result of humidity. |

| − | * '''[[ | + | * '''[[Haptic evaluation of leather surfaces|Haptic]]''': Leather should have the desired feel. |

| − | * ''' | + | * '''Climate Alternating Test''': Leather should be weather-resistant. |

| − | * '''[[ | + | * '''[[Gloss of leather|Degree of gloss]]''': Leather should have the desired degree of gloss. |

| − | * ''' | + | * '''Back polishing''': Leather should not lose the desired gloss level during use. |

| − | * '''[[ | + | * '''[[Soiling behavior - Anti-Soiling|Soiling behaviour]]''': Leather should not easily get dirty. |

| − | * '''[[ | + | * '''[[Creaking noise]]''': Leather should not make undesired friction noise when moved. |

| − | * ''' | + | * '''[[Leather smell|Smell]]''': Leather should not smell or it should have a pleasant odour. |

| − | * ''' | + | * '''[[Leather emission]]''': Leather should not evaporate any substances. |

| + | * '''Alcohol resistance''': Drop Test. Resistance to e.g. disinfectants. | ||

| + | * '''Sea water resistance''': Resistance of [[Marine & Boat leather|boat leather]] to sea water. | ||

| + | |||

| + | |||

| + | <p align=center> | ||

| + | [[bild:Materialzerstörend-01.jpg|500px]] | ||

| + | </p> | ||

<p align=center> | <p align=center> | ||

| − | + | [[bild:Stanzen-Proben-01.jpg|500px]] | |

| − | [[bild:Stanzen-Proben-01.jpg| | + | |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Usually material-destructive tests are necessary to check the leather quality. - Samples are [[Leather cutting|punched]] out of the leather.''<br></p> |

<p> </p> | <p> </p> | ||

| − | + | The extensive testing standards set by manufacturers means[[Car leather|car leather]] is very similar and uniform across the board. Most are monochrome, [[Finish|surface-coloured]] [[Smooth leather|smooth leather]]. | |

| Line 158: | Line 193: | ||

| − | == | + | ==Standards of quality leather== |

| − | + | There are countless national and international standards to determine the quality of leather. Also, the labelling of leather products is regulated by national and international standards. Additionally, many leather manufacturing and processing companies have extra internal standards and requirements. | |

| − | + | Overall, the standards set for the quality of leather are correct and necessary. But they are also filled with a lot of grey areas, loopholes and weaknesses. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | In Europe, confusing rules exist on labelling of [[Split leather|split leather]]. In some cases, the [[Types of leather|type of leather]] must be declared and in some cases not. In Germany for instance, [[Split leather#coated split leather|coated split leather]] is used in vehicles, without the obligation to inform the customer. An end user cannot differentiate between the two. When the surface of split leather is embossed with a grain structure it is virtually impossible to tell the difference. In such cases, the standards must do more to ensure transparency, so the customer knows exactly what [[Types of leather|type of leather]] they are getting. | ||

| − | + | Standards are often referred to when seeking a verifiable solution or to reach verdicts in legal disputes. However, they are inconsistent, ambiguous and open to interpretation. They do not mention when one particular rule or standard should take priority over the other. An end consumer must be able to find out the quality of the material and be able to compare prices and qualities. The leather standards and norms must do more to protect the end consumer by ensuring dealers and manufacturers provide clear, transparent information. | |

| − | |||

| − | + | ==Test equipment== | |

| + | To test the various requirements for leather, there is a wide variety of devices. | ||

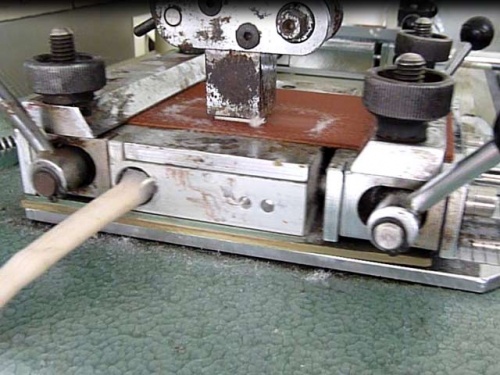

| − | + | * '''[[Rub fastness of leather|VESLIC rubbing test]]''': The rubbing test checks the dry abrasion and wet abrasion qualities of leather. Wool felts are rubbed dry and wet in a specified number of times over the leather. The wear in daily use and the tendency to discolouration is examined. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Reibtest-03.jpg| | + | [[bild:Reibtest-03.jpg|250px]] |

| − | [[bild:Reibtest-02.jpg| | + | [[bild:Reibtest-02.jpg|250px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | [[bild:Reibtest-01.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''[[Rub fastness of leather|VESLIC rubbing test]].''<br></p> | ||

<p> </p> | <p> </p> | ||

| − | * ''' | + | * '''[[Leather flexometer test]]''': This test examines the leather's wrinkle resistance by folding the leather multiple times in all directions. |

| + | In particular, [[Leather shoes|shoe upper leather]] gets buckled during walking and needs a special resistance to [[Leather damages|breakage]]. The "Bally Flexometer" named after its inventor is a commonly used instrument and method to test resistance. It is also used for [[Car leather|car leather]], [[Leather furniture|furniture leather]], [[Leather clothing|clothing leather]] and other leather applications. | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Bally-Test-02.jpg| | + | [[bild:Bally-Test-02.jpg|500px]] |

| − | [[bild:Bally-Test-01.jpg| | + | </p> |

| + | <p align=center> | ||

| + | [[bild:Bally-Test-01.jpg|500px]] | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''[[ | + | ''[[Leather flexometer test|Bally Flexometer]]''<br></p> |

<p> </p> | <p> </p> | ||

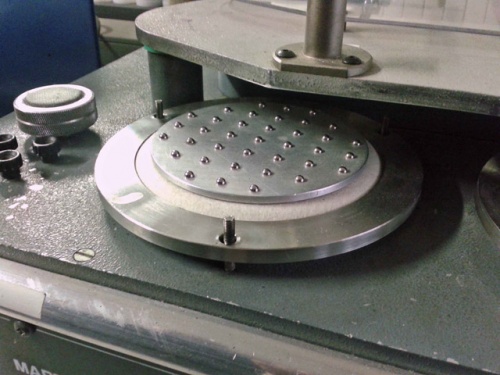

| − | * ''' | + | * '''Taber abrasion tester''': The Taber abrasion tester checks resistance of various materials. The Taber Abrasion test is an internationally recognised test method. Abrasion resistance is tested using two friction rollers that are pressed with a predetermined force to the test material, which rotates below the friction rollers. This simulates a combination of scraping, sliding, squeezing, thwarting and abrasion. |

<p align=center> | <p align=center> | ||

| − | [[bild:Taber- | + | [[bild:Leather-Taber-test-01.jpg|500px]] |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | [[bild:Taber-Tester-01.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Taber abrasion tester.''<br></p> | ||

<p> </p> | <p> </p> | ||

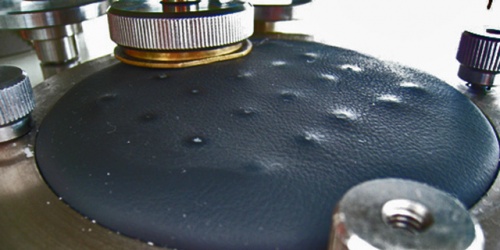

| − | *''' | + | *'''Martindale method''': The Martindale rub test examining the abrasion resistance of upholstery leather. |

<p align=center> | <p align=center> | ||

| − | [[bild:Martindale-Kugelplatte-02.jpg| | + | [[bild:Martindale-Kugelplatte-02.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Martindale | + | [[bild:Martindale-Kugelplatte-01.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Martindale rub test - Martindale method''<br></p> | ||

<p> </p> | <p> </p> | ||

| Line 299: | Line 264: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''The ball plate test simulates selective frictional stress.''<br></p> |

<p> </p> | <p> </p> | ||

| − | * '''[[ | + | * '''[[Colour fastness - Light fastness of leather|Light fastness - Xenon tester]]''': The xenon tester validates the effect of light on surfaces. Sunlight causes rapid [[Leather damages|ageing]] of materials. In the test, a xenon arc lamp is used as a radiation source, wherein the filtered spectrum has similarity to the sunlight. The xenon test is suitable for all paints, textiles, plastics etc. |

<p align=center> | <p align=center> | ||

| − | [[bild: | + | [[bild:Light fastness test leather-01.jpg|500px]] |

| − | [[bild: | + | </p> |

| + | <p align=center> | ||

| + | [[bild:Lichtalterung-01.jpg|500px]] | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''[[Colour fastness - Light fastness of leather|Light fastness]] test - [[Aniline leather]] and [[Semi-aniline|semi-aniline]] are natural and [[Haptic evaluation of leather surfaces|soft]], but [[Colour fastness - Light fastness of leather|fade]] more easily.''<br></p> |

<p> </p> | <p> </p> | ||

| − | + | The change in colour can be checked with measuring devices. The scale of difference is measured in delta value. Delta DEcmc is a number that represents the distance between colours. The difference in colour depends mainly on two factors: 1) the variation in brightness and 2) the tone of the colour itself. For example, a leather can turn from blue into green, without noticeable change in the measured brightness. A variation tolerance of delta value of 1 is usually considered acceptable. However, the automotive industry requires a maximum delta of 0.5, which is difficult to achieve. Surface irregularities of the [[Grain side|grain texture]] or different [[Gloss of leather|degrees of gloss]] can also change the delta value. Even within an area, the delta value can vary up to 0.5 due to differences in the grain texture. | |

| − | |||

| + | Photos below show a deviation in Delta DEcmc of 6.6 because of fading following a Xenon test | ||

| + | |||

| + | <p align=center> | ||

| + | [[bild:Xenon-Test-Leder-01.jpg|500px]] | ||

| + | </p> | ||

<p align=center> | <p align=center> | ||

| − | + | [[bild:Xenon-Test-Leder-02.jpg|500px]] | |

| − | [[bild:Xenon-Test-Leder-02.jpg| | + | |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''The Xenon-tester shows the [[Colour fastness - Light fastness of leather|light sensitivity]]. The [[Finish|finish]] is recognisably |

| + | faded. DEcmc 6.6.''<br></p> | ||

<p> </p> | <p> </p> | ||

| Line 332: | Line 303: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''[[ | + | ''[[Aniline leather]] day 0, day 16 and day 50 - [[Colour fastness - Light fastness of leather|faded]] in daily sunlight.''<br></p> |

<p> </p> | <p> </p> | ||

| − | == | + | ==Quality differences== |

| − | + | It is difficult for the inexperienced consumer to judge the quality of leather. Even an expert will not be able to identify and recognise every defect with their naked eye. Experience is needed to discover differences in quality and the majority of quality criteria can only be tested in the laboratory. | |

| + | The aim and purpose of this dictionary is to help people understand leather. For buying furniture, we have [[Leather furniture#What should be considered when buying new leather furniture?|additional guidelines]]. | ||

| − | + | Price and quality go hand-in-hand. If a leather object is particularly inexpensive, in most cases it's not valuable. Branded products have usually undergone extensive tests to ensure their quality. Manufacturers who evidently endeavour to improve the quality of their products and to describe the origin and quality of the leather, usually have a good quality end product. This also applies to established dealers. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | ' | + | |

| − | + | ||

| − | + | [[Car leather|Leather in vehicles]] has quite rugged qualities due to the purchasing power and strict quality controls performed by manufacturers. The leather is not particularly soft and natural, but highly durable. [[Leather furniture|Furniture leathers]] have greater variation in quality due to the large number of vendors. | |

| − | + | ||

| − | + | Even if the leather is of good quality, over time and due mainly due to wear, the top layer of [[Leather damages|colouration rubs off]]. The leather itself remains undamaged. However, if the leather itself is unstable, it [[Leather damages|deteriorates]] under the colour layer and the [[Finish|colour binder]] alone cannot compensate for this lack of stability in the fibre structure. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <p align=center> | ||

| + | [[bild:Moebel-Abrieb-01.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | [[bild:KFZ-Abrieb-01.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Typical [[Leather damages|wear]] in [[Car leather|car]] and [[Leather furniture|furniture leather]] of good quality.''<br></p> | ||

| + | <p> </p> | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Moebel- | + | [[bild:Moebel-Brüche-02.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | + | [[bild:Moebel-Brüche-01.jpg|500px]] | |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Typical breakage in leather with [[leather quality#Types of leather - Leather quality - Ease of maintenance|poorer quality leather]]. The leather under the finish breaks or is more stretchable than the finish.''<br></p> | ||

<p> </p> | <p> </p> | ||

<p align=center> | <p align=center> | ||

| − | [[bild: | + | [[bild:Hard-finish-crack-leather-02.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Cracks in the [[finish]] due to poor [[Crosslinker#Spinn web effect by aziridine crosslinker|finish quality]]. The finish cracks on the intact leather.''<br></p> |

<p> </p> | <p> </p> | ||

| − | == | + | In order to be able to assess whether a [[leather damages|leather damage]] is a quality deficiency or typical ageing behavior, many aspects have to be considered. No leather is immortal and, depending on the [[Types of leather|leather type]], type of usage and load, [[leather care|intensity of maintenance]] and age of the leather, a leather damage can be typical ageing behavior or a quality deficiency. |

| − | + | ||

| + | |||

| + | ==Variations in quality== | ||

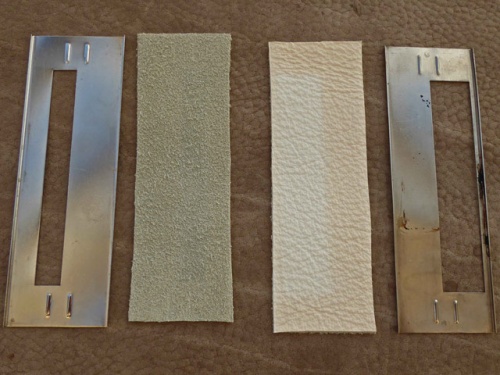

| + | We have already identified how the quality of leather can vary drastically, depending on the [[Parts of the hide|section of the hide]]. Therefore, it may happen that different leather qualities appear within a leather item. This is often seen in [[Leather furniture|furniture]] and [[Leather clothing|clothing]]. | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Lederqualität-01.jpg| | + | [[bild:Lederqualität-01.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| + | [[bild:Lederqualität-02.jpg|250px]] | ||

[[bild:Lederqualität-03.jpg|250px]] | [[bild:Lederqualität-03.jpg|250px]] | ||

| − | |||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | [[bild:Lederqualität-04.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''[[Leather furniture|Furniture leather]] where adjacent areas have different qualities and therefore aged differently.''<br></p> | ||

<p> </p> | <p> </p> | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Lederqualität-05.jpg| | + | [[bild:Lederqualität-05.jpg|500px]] |

| − | [[bild:Lederqualität-06.jpg| | + | </p> |

| + | <p align=center> | ||

| + | [[bild:Lederqualität-06.jpg|500px]] | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''[[Leather furniture|Furniture leather]] with different [[Colour fastness - Light fastness of leather|fading]] behaviour.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 407: | Line 385: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Car headrest - even when equal pressure is applied within different areas of the same leather, a varying number of wrinkles appears. In the border region [[Loose grain leather|loose grain leather]] becomes visible.''<br></p> |

<p> </p> | <p> </p> | ||

| − | == | + | ==[[Types of leather]] - Leather quality - [[Leather care|Ease of maintenance]]== |

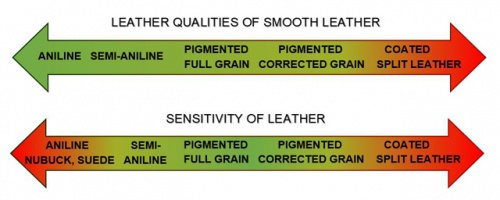

| − | + | Most assume that the best quality leather would be the least sensitive and easiest to [[Leather care|maintain]]. But as with textiles or precious metals (silk is very sensitive and gold is not scratch resistant), the sensitivity in the highest price bracket and quality segment is much higher. Valuable objects often require more and better care than cheaper items. This also applies to the different [[Types of leather|types of leather]]. | |

<p align=center> | <p align=center> | ||

| − | [[bild: | + | [[bild:Leather-Quality-Leather-Sensitivity.jpg|500px]] |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Comparison of leather quality and [[Leather care|ease of maintenance]].'' |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''[[ | + | ''[[Suede]] - [[Nubuck]] - [[Aniline leather]] - [[Semi-aniline]] - [[Corrected grain]] - [[Split leather#coated split leather|Coated split leather]]''<br></p> |

<p> </p> | <p> </p> | ||

| − | + | Frequently asked questions: | |

| − | * '' | + | * ''Why is [[Aniline leather]], [[Nubuck|nubuck]] and [[Suede|suede]] less [[Leather care|easy to maintain]]?'' They are [[Open pore leather|porous leather]] and therefore more [[Leather cleaner|sensitive to stains]]. |

| − | * '' | + | * ''Why is [[Aniline leather]] evaluated with best quality?'' Because aniline leather is especially [[Haptic evaluation of leather surfaces|natural and warm]]. |

| − | * '' | + | * ''Why is [[Split leather#Coated split leather - Laminated split leather|coated split leather]] less easy to maintain?'' It is more unstable, what cannot be improved by care and classic [[Leather care|leather care products]] harms some types of split leather coatings. |

| − | * '' | + | * ''Are there exceptions to the rules?'' |

| − | + | LEATHER QUALITY: An [[Aniline leather|aniline leather]] could theoretically tear unexpectedly or have an [[Leather smell|undue smell]] or the leather colour might [[Dye transfer from leather|rub off]]. Then it is of poor quality. A [[Smooth leather|smooth leather]] can be [[Corrected grain|fine sanded]] and carefully [[Embossed leather|embossed]] and feel like a semi-aniline leather. Then it may be better than a normal, [[Finish|pigmented]] smooth leather. | |

| − | [[ | + | But, in most cases, the leather corresponds to the expectations. [[Aniline leather]] is more expensive because hides without [[Natural markings on leather|skin damages]] are rare. Therefore, more effort is applied in [[Tanning leather|manufacturing]] of such leather.<br /> |

| + | [[Leather care|EASY-CARE]]: Every [[Types of leather|type of leather]] has its own qualities. As long as the information provided by manufacturers and dealers at the outset is accurate, the leather should adhere to its usual qualities. Problems may occur when [[Leather cleaner|cleaning]] and [[Leather care|maintenance]] if the leather is genuinely of a poor quality. But this is seldom. | ||

| − | |||

| − | + | '''Conclusion:''' [[Semi-aniline]] and [[Finish|pigmented smooth leather]] are the gold standard for leathers in constant use. They are comfortable, natural and easier to maintain as the remaining [[Types of leather|types of leather]], but also cost a bit more. For price-conscious buyers [[Corrected grain|corrected grain leather]] is a good choice. | |

| − | == | + | ==Seal of approval for leather== |

| − | + | In addition to the relevant standards and laws for leather, organizations issue seals of quality and certificates or companies undertake on their own initiative to meet minimum requirements for their leather quality that exceed the requirements of the laws and standards. It is often about the environment, social aspects and [[Leather sustainability and traceability|animal welfare]]. These voluntary requirements go in different directions and there are various variants of self-commitments. | |

| − | + | ||

| − | + | The [[The Blue Angel|Blue Angel]] is issued by RAL GmbH and focuses on [[Leather furniture|furniture leather]] and, among other aspects, attaches great importance to environmentally friendly production, a final product that is not harmful to health and harmless disposal. The "[[Natural leather|NATURLEDER IVN certified]]" certification places value on social and environmental aspects and dispenses with [[Chrome tanned|chrome tanning]] and surface pigmentation of the leather. The Identity Leather from the [http://www.identity-leder.de/?lang=en Meindl company] ensures the [[Leather sustainability and traceability#Leather traceability|traceability]] of leather back to the farm in order to ensure species-appropriate animal husbandry. | |

| − | + | ||

| − | * [[ | + | |

| − | * [[ | + | ==Additional information== |

| − | * [[ | + | * [[Leather sustainability and traceability]] |

| + | * [[The biodegradability of leather]] | ||

| + | * [[Environmental protection]] | ||

| + | * [[The Blue Angel]] | ||

| + | * [[Oeko-Tex Leather Standard]] | ||

| + | * [[Sustainable Leather Foundation SLF]] | ||

| + | * [[Natural leather#NATURLEDER IVN certified|NATURLEDER IVN certified]] | ||

| + | * [[Leather damages|Typical age-appropriate leather damages and atypical due to quality problems occurring leather damage]] | ||

| + | * [[Chrome VI - Chromium VI]] | ||

| + | * [[Basic rules when dealing with leather]] | ||

<br> | <br> | ||

| − | * [[ | + | * [[Rawhide]] |

| − | * [[ | + | * [[Leather batch]] |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | < | + | <logoplustext /> |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

[[Kategorie:All Articles]] | [[Kategorie:All Articles]] | ||

[[Kategorie:Leather production]] | [[Kategorie:Leather production]] | ||

| − | [[Kategorie: | + | [[Kategorie:Miscellaneous Leather items]] |

Latest revision as of 18:52, 24 July 2023

Contents

- 1 What is leather quality?

- 2 Leather testing - leather properties

- 3 Criteria of quality leather

- 4 Standards of quality leather

- 5 Test equipment

- 6 Quality differences

- 7 Variations in quality

- 8 Types of leather - Leather quality - Ease of maintenance

- 9 Seal of approval for leather

- 10 Additional information

What is leather quality?

It is easy to identify the vast differences in skin quality that exist from one species to another. Leather is not always equal in quality. Gender, age, nutrition, feeding and general care all affect an animal's skin. Also there may be differences within a skin of one animal. Below we explain how some of these factors can affect skin quality.

Differences in quality of cow leather (but also applies to other species):

- Age: The quality of hides from older animals is generally poorer than that of younger animals.

- Gender: Female hides have a denser fibre structure and a finer grain structure.

- Gender specific activities: The stability of the skin's fibre structure deteriorates the more often a male animal mates and, for a female, the number of times she gives birth. Castrated oxen tend to have a finer skin structure.

- Nutrition: Fresh forage promotes better quality skin.

- Animal husbandry: The skin of animals kept on open pastures has a superior texture.

- Climate: A harsh and cold climate promotes a good skin quality. A rule of thumb is that hides from above the 37th parallel are of better quality.

Leather is used for many different applications. As car leather, for shoes, for leather straps and belts, for leather suits or buttery soft leather gloves. Diverse demands are placed on leather, depending on its use. Furniture leather should be easy to maintain, while being soft and warm. Shoe leather should be robust, waterproofed, soft, heat-retaining and breathable. Car leather should be easy to maintain and should be impervious to heat, cold and wear.

However it's used, leather should be durable and easy to clean. It should not tear, bleach, smell unpleasant or contain pollutants. These are the essential "leather qualities" or "leather properties".

However, leather can't be soft, robust and easy to clean and maintain all at the same time. Neither can it be paper thin and soft and also tear-proof. Optical influences such as embossing or the degree of gloss also influence the parameters and can help or hinder the fulfillment of other parameters.

The art of tanning determines the correct coordination of all wishes and the fulfillment of necessary parameters. Over many work steps in leather production, a suitable end result is worked towards by tanners, which can then be reproduced as best as possible for the customer. Depending on the type of leather, these challenges are enormous and require a lot of experience with more difficult types of leather such as open-pored smooth leather.

In particular, the sensitivity of especially high quality leather, such as the soft aniline leather of a luxury leather jacket, of exotic leather or of an expensive set of furniture is often misjudged. Because the object was so expensive customers therefore expect that it would be very easy to clean and maintain the leather. But quite the opposite is true. Valuable leathers are as sensitive as silk. With regular use the beauty diminishes rapidly, while incorrect cleaning can even ruin the material.

A good leather feels warm and soft, but is also more sensitive.

Car leather is considered to be particularly robust. Most of the vehicle manufacturers require more than 40 quality criteria that must be fulfilled. Stringent wear tests must be passed. It must be resistant to suntan lotion and bug spray. Many chemicals are not allowed to be used and the leather emission level is tested. As a result, the leather is extremely durable, but no longer soft and warm to the touch.

The tanner and the producer of a leather object therefore should establish their own, verifiable quality parameters, depending on the desired properties of leather. These parameters should take into account the animal species and the rawhide. Differences in the quality of the individual sections of a skin, including the possibility of skin damage when cutting, must also be considered. Only a limited quantity of skins can be worked upon at any given time during the manufacturing process of leather and all of them do not behave the same in each run. Often the tanner will need to make minor changes during the process, which can lead to deviations from one batch to another. Differences can be detected depending on the quality control limits set.

Apart from the production quality, the longevity of leather depends on certain other factors too. An important element for long-lasting pleasure of a a leather object is the handling of it. If leather is regularly cleaned and maintained and not excessively overused and if the basic rules in dealing with leather are respected, you will prolong the enjoyment of this durable and robust material.

Leather testing - leather properties

There are many different methods for testing and evaluating leather properties. For a layman, only rough and basic testing options are available when purchasing a good and beautiful leather item. Some of the criteria can be checked directly as an end customer, but when certain criteria cannot be tested, don't be afraid to ask the vendor the right questions. Below we list some basic checks that can be carried out.

- Look of the leather: A beautiful top quality leather looks very natural and does not contain markings on the surface.

- Leather grain texture: The grain texture should look good and be as natural as possible. An embossed grain pattern is very uniform, which does not correspond to the natural grain of a skin and embossed leather often feels less natural.

- Softness of the leather: Generally, leather should be soft to the touch and have a natural feel. But leather shoes or leather belts require a certain strength.

- Haptic evaluation of leather surfaces: Leather should feel good, whether it's soft, blunt or smooth. The more beautiful leather feels, the better its quality.

- The leather finish: To protect the leather, it is often useful to apply a binder-based finish to the surface. The more layers of leather paint are applied, the more unnatural it feels. If the grain texture issanded before the finish, the leather feels even more unnatural. So too does film-coated leather, usually considered to be inferior to natural leather and therefore relatively inexpensive. On the other hand, the effect is an accepted feature of patent leather.

- Breathability of leather: An advantage of leather over alternative materials is its breathability. But the more a leather is coated with leather colour or a film, the lower the breathability.

- Tear strength and stability of the leather: Good leather is stable and resistant to tearing, wheareas suede, nubuck or extremely soft lambskin will not have the same stability as, for example, a belt leather. But within the types of leather very different qualities exist. So, an inferior quality leather within the same type of leather will always tear more easily than that of a higher quality. Also sanded leather is usually less stable than full-grain leather.

The causes of damages of a leather couch.

Criteria of quality leather

To determine whether a leather corresponds to the desired quality requirements, it passes through a series of testing processes. Extremely high and strict standards are set, particularly in the automotive industry. Minimum qualities are set and controlled also for furniture, shoes and garment leather. In addition, there are statutory testing regulations for harmful substances, which is also a sign of quality.

In the manufacturing of leather, the leather quality is constantly checked using all senses and with test equipment.

Although the specific test standards vary by manufacturer and are chosen according to the intended use of the leather, the tested properties are quite uniform.

Further rules on permitted ingredients in leather are regulated by national laws.

Test criteria for the leather quality include (and is regulated in many national and international standards):

- Breathability: The ability to absorb sweat through to the opposite side.

- Weight: Important e.g. for aircraft leather, because it should weigh as little as possible to reduce fuel costs.

- Thickness of leather: The thickness has an influence on the stability of leather.

- Tensile strength - Tear strength: If the leather is drawn (for example, more than 200 N per 5 cm).

- Tear force: Leather should not easily tear further (for example, desirable: more than 20 N).

- Adhesiveness of the finish: The colour layers on the surface should not come off (for example, desirable: more than 25 N per 5 cm).

Test of the adhesiveness of the finish.

- Flammability and fire retardancy of leather: Important for aircraft, nursing homes, public buildings etc.

Flame-retardant leather.

Devices for testing the fire protection properties.

- Rub fastness: Dry, wet, alkaline. The surface should not change in friction or wear zones.

- Light fastness: Leather should not fade.

- Flexibility: Desirable: robustness in more than 100,000 cycles. Leather should be extensible, but not baggy.

- Buckling behaviour: Leather should not break in folds. Desirable: 30,000 folds without damage.

- Water permeability: Leather should be waterproof.

Laboratory test of the water-repellent properties of a nubuck leather.

- Acid and alkali resistance: The leather surface should be resistant to chemicals as much as possible.

- Hydrolysis resistance: Leather should not decay as a result of humidity.

- Haptic: Leather should have the desired feel.

- Climate Alternating Test: Leather should be weather-resistant.

- Degree of gloss: Leather should have the desired degree of gloss.

- Back polishing: Leather should not lose the desired gloss level during use.

- Soiling behaviour: Leather should not easily get dirty.

- Creaking noise: Leather should not make undesired friction noise when moved.

- Smell: Leather should not smell or it should have a pleasant odour.

- Leather emission: Leather should not evaporate any substances.

- Alcohol resistance: Drop Test. Resistance to e.g. disinfectants.

- Sea water resistance: Resistance of boat leather to sea water.

Usually material-destructive tests are necessary to check the leather quality. - Samples are punched out of the leather.

The extensive testing standards set by manufacturers meanscar leather is very similar and uniform across the board. Most are monochrome, surface-coloured smooth leather.

Standards of quality leather

There are countless national and international standards to determine the quality of leather. Also, the labelling of leather products is regulated by national and international standards. Additionally, many leather manufacturing and processing companies have extra internal standards and requirements.

Overall, the standards set for the quality of leather are correct and necessary. But they are also filled with a lot of grey areas, loopholes and weaknesses.

In Europe, confusing rules exist on labelling of split leather. In some cases, the type of leather must be declared and in some cases not. In Germany for instance, coated split leather is used in vehicles, without the obligation to inform the customer. An end user cannot differentiate between the two. When the surface of split leather is embossed with a grain structure it is virtually impossible to tell the difference. In such cases, the standards must do more to ensure transparency, so the customer knows exactly what type of leather they are getting.

Standards are often referred to when seeking a verifiable solution or to reach verdicts in legal disputes. However, they are inconsistent, ambiguous and open to interpretation. They do not mention when one particular rule or standard should take priority over the other. An end consumer must be able to find out the quality of the material and be able to compare prices and qualities. The leather standards and norms must do more to protect the end consumer by ensuring dealers and manufacturers provide clear, transparent information.

Test equipment

To test the various requirements for leather, there is a wide variety of devices.

- VESLIC rubbing test: The rubbing test checks the dry abrasion and wet abrasion qualities of leather. Wool felts are rubbed dry and wet in a specified number of times over the leather. The wear in daily use and the tendency to discolouration is examined.

- Leather flexometer test: This test examines the leather's wrinkle resistance by folding the leather multiple times in all directions.

In particular, shoe upper leather gets buckled during walking and needs a special resistance to breakage. The "Bally Flexometer" named after its inventor is a commonly used instrument and method to test resistance. It is also used for car leather, furniture leather, clothing leather and other leather applications.

- Taber abrasion tester: The Taber abrasion tester checks resistance of various materials. The Taber Abrasion test is an internationally recognised test method. Abrasion resistance is tested using two friction rollers that are pressed with a predetermined force to the test material, which rotates below the friction rollers. This simulates a combination of scraping, sliding, squeezing, thwarting and abrasion.

Taber abrasion tester.

- Martindale method: The Martindale rub test examining the abrasion resistance of upholstery leather.

Martindale rub test - Martindale method

The ball plate test simulates selective frictional stress.

- Light fastness - Xenon tester: The xenon tester validates the effect of light on surfaces. Sunlight causes rapid ageing of materials. In the test, a xenon arc lamp is used as a radiation source, wherein the filtered spectrum has similarity to the sunlight. The xenon test is suitable for all paints, textiles, plastics etc.

Light fastness test - Aniline leather and semi-aniline are natural and soft, but fade more easily.

The change in colour can be checked with measuring devices. The scale of difference is measured in delta value. Delta DEcmc is a number that represents the distance between colours. The difference in colour depends mainly on two factors: 1) the variation in brightness and 2) the tone of the colour itself. For example, a leather can turn from blue into green, without noticeable change in the measured brightness. A variation tolerance of delta value of 1 is usually considered acceptable. However, the automotive industry requires a maximum delta of 0.5, which is difficult to achieve. Surface irregularities of the grain texture or different degrees of gloss can also change the delta value. Even within an area, the delta value can vary up to 0.5 due to differences in the grain texture.

Photos below show a deviation in Delta DEcmc of 6.6 because of fading following a Xenon test

The Xenon-tester shows the light sensitivity. The finish is recognisably

faded. DEcmc 6.6.

Aniline leather day 0, day 16 and day 50 - faded in daily sunlight.

Quality differences

It is difficult for the inexperienced consumer to judge the quality of leather. Even an expert will not be able to identify and recognise every defect with their naked eye. Experience is needed to discover differences in quality and the majority of quality criteria can only be tested in the laboratory.

The aim and purpose of this dictionary is to help people understand leather. For buying furniture, we have additional guidelines.

Price and quality go hand-in-hand. If a leather object is particularly inexpensive, in most cases it's not valuable. Branded products have usually undergone extensive tests to ensure their quality. Manufacturers who evidently endeavour to improve the quality of their products and to describe the origin and quality of the leather, usually have a good quality end product. This also applies to established dealers.

Leather in vehicles has quite rugged qualities due to the purchasing power and strict quality controls performed by manufacturers. The leather is not particularly soft and natural, but highly durable. Furniture leathers have greater variation in quality due to the large number of vendors.

Even if the leather is of good quality, over time and due mainly due to wear, the top layer of colouration rubs off. The leather itself remains undamaged. However, if the leather itself is unstable, it deteriorates under the colour layer and the colour binder alone cannot compensate for this lack of stability in the fibre structure.

Typical wear in car and furniture leather of good quality.

Typical breakage in leather with poorer quality leather. The leather under the finish breaks or is more stretchable than the finish.

Cracks in the finish due to poor finish quality. The finish cracks on the intact leather.

In order to be able to assess whether a leather damage is a quality deficiency or typical ageing behavior, many aspects have to be considered. No leather is immortal and, depending on the leather type, type of usage and load, intensity of maintenance and age of the leather, a leather damage can be typical ageing behavior or a quality deficiency.

Variations in quality

We have already identified how the quality of leather can vary drastically, depending on the section of the hide. Therefore, it may happen that different leather qualities appear within a leather item. This is often seen in furniture and clothing.

Furniture leather where adjacent areas have different qualities and therefore aged differently.

Furniture leather with different fading behaviour.

Car headrest - even when equal pressure is applied within different areas of the same leather, a varying number of wrinkles appears. In the border region loose grain leather becomes visible.

Types of leather - Leather quality - Ease of maintenance

Most assume that the best quality leather would be the least sensitive and easiest to maintain. But as with textiles or precious metals (silk is very sensitive and gold is not scratch resistant), the sensitivity in the highest price bracket and quality segment is much higher. Valuable objects often require more and better care than cheaper items. This also applies to the different types of leather.

Comparison of leather quality and ease of maintenance.

Suede - Nubuck - Aniline leather - Semi-aniline - Corrected grain - Coated split leather

Frequently asked questions:

- Why is Aniline leather, nubuck and suede less easy to maintain? They are porous leather and therefore more sensitive to stains.

- Why is Aniline leather evaluated with best quality? Because aniline leather is especially natural and warm.

- Why is coated split leather less easy to maintain? It is more unstable, what cannot be improved by care and classic leather care products harms some types of split leather coatings.

- Are there exceptions to the rules?

LEATHER QUALITY: An aniline leather could theoretically tear unexpectedly or have an undue smell or the leather colour might rub off. Then it is of poor quality. A smooth leather can be fine sanded and carefully embossed and feel like a semi-aniline leather. Then it may be better than a normal, pigmented smooth leather.

But, in most cases, the leather corresponds to the expectations. Aniline leather is more expensive because hides without skin damages are rare. Therefore, more effort is applied in manufacturing of such leather.

EASY-CARE: Every type of leather has its own qualities. As long as the information provided by manufacturers and dealers at the outset is accurate, the leather should adhere to its usual qualities. Problems may occur when cleaning and maintenance if the leather is genuinely of a poor quality. But this is seldom.

Conclusion: Semi-aniline and pigmented smooth leather are the gold standard for leathers in constant use. They are comfortable, natural and easier to maintain as the remaining types of leather, but also cost a bit more. For price-conscious buyers corrected grain leather is a good choice.

Seal of approval for leather

In addition to the relevant standards and laws for leather, organizations issue seals of quality and certificates or companies undertake on their own initiative to meet minimum requirements for their leather quality that exceed the requirements of the laws and standards. It is often about the environment, social aspects and animal welfare. These voluntary requirements go in different directions and there are various variants of self-commitments.

The Blue Angel is issued by RAL GmbH and focuses on furniture leather and, among other aspects, attaches great importance to environmentally friendly production, a final product that is not harmful to health and harmless disposal. The "NATURLEDER IVN certified" certification places value on social and environmental aspects and dispenses with chrome tanning and surface pigmentation of the leather. The Identity Leather from the Meindl company ensures the traceability of leather back to the farm in order to ensure species-appropriate animal husbandry.

Additional information

- Leather sustainability and traceability

- The biodegradability of leather

- Environmental protection

- The Blue Angel

- Oeko-Tex Leather Standard

- Sustainable Leather Foundation SLF

- NATURLEDER IVN certified

- Typical age-appropriate leather damages and atypical due to quality problems occurring leather damage

- Chrome VI - Chromium VI

- Basic rules when dealing with leather

a kotori web solution

a kotori web solution