Difference between revisions of "Chrome tanned"

| (38 intermediate revisions by one user not shown) | |||

| Line 4: | Line 4: | ||

| − | == | + | ==History of chrome tanning== |

| − | + | Until the 19th century, there was little development in the [[tanning|tanning process]]. While there was some use of [[Tawing with alum|alum (aluminium) salts]] and [[tanning#Tanning methods|other tanning methods]], [[vegetable-tanned leather|vegetable tanning]] was the most prevalent. In 1858, chrome tanning was invented by the German technologist Friedrich Knapp and Hylten Cavalin from Sweden. However, it was an American chemist called Augustus Schultz who first patented the chrome tanning process with alkaline chromium (III) sulfate as [[Tannins|tanning agent]]. | |

| − | ' | + | Chromium(III) occurs naturally in the Earth's crust. It is often found in the form of chromium minerals such as chromite or chromite spinel. The largest deposits of chromite minerals are located in South Africa, Kazakhstan, India, Russia, Turkey, the Philippines, and Zimbabwe. Chromium(III) is extracted from these ores and converted into various compounds to fulfill its different applications. |

| − | + | ||

| − | |||

| − | + | <p align=center> | |

| + | [[bild:Ball-Chrome-tanning-1920.jpg|500px]] | ||

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Beginnings of chrome tanning: Ball of chrome-tanned cow leather from before 1920 ([[Leather museum|© German Ledermuseum, C. Perl-Appl]]).''<br></p> | ||

| + | <p> </p> | ||

| + | |||

| + | In the following decades, chrome tanning became the most common and dominant form of [[tanning]]. One of the main reasons why it was adopted so rapidly is that the process was much faster than [[Vegetable-tanned leather|vegetable tanning]]. In addition, the temperature resistance of chrome-tanned leather was an important factor in [[Leather shoes|shoe manufacture]]. The vulcanization of rubber creates heat that chrome-tanned leather tolerates without [[Shrunken leather - leather shrinkage|shrinking]]. With chrome-tanned leather, the rubber soles could be vulcanized (connected) to the [[Leather shoes|upper leather]] of the shoes without having to sew the sole to the upper leather. That was a big cost saving in industrial shoe manufacturing which is still valid today and cannot be achieved by other [[Tanning leather|tanning methods]]. Another benefit of chrome-tanned leather was weight. [[Vegetable-tanned leather|Vegetable-tanned leather]] is stronger and heavier, but lightweight chrome-tanned leather was more popular for [[leather shoes|children's or women's shoes]]. | ||

| + | |||

| + | The invention of chrome tanning coincided with the discovery of the [[Oils & fats in the leather industry#fatliquoring (regreasing)|fatliquoring (regreasing)]] process and also the development of [[leather colour|synthetic dyes]]. Together these changes to the chemistry of leather production led to chrome tanning becoming the preferred method. Chromium salts belong to the group of [[Mineral tanning|mineral tannins]]. | ||

| + | |||

| + | Immediately after tanning, the leather is still wet and is tinged with blue, hence it is also referred to as [[wet blue]]. | ||

<p align=center> | <p align=center> | ||

| − | [[bild:ChromIII-01.jpg| | + | [[bild:ChromIII-01.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | [[bild:ChromIII-02.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Chromium (III) oxide in powder form.''<br></p> | ||

<p> </p> | <p> </p> | ||

| − | == | + | ==The global importance of chrome tanning== |

| − | + | Chrome tanning with chromium (III) salts accounts for around 85 percent of global [[leather production]] (as per 2014). 95% of [[leather shoes|shoe upper leather]], 70% of [[leather furniture|leather upholstery]] (but decreasing in favour of [[Chrome tanned#Chrome-free leather - FOC = Free of Chrome|FOC-leather)]] and almost 100% of [[Leather clothing|clothing leather]] are chrome tanned. | |

| − | + | Although it has twice the tensile strength of [[Vegetable-tanned leather|vegetable tanned leather]], chrome-tanned leather weighs less because the skin does not fully absorb the chromium salts used for tanning. The tannin makes up just 4% (with newer leathers only about 1.5%) of the leather weight, while [[vegetable-tanned leather]] has a tannin content of about 20 percent. | |

| − | + | Chrome-tanned leather is more easily [[Waterproofing leather|hydrophobized]] compared to other tanning alternatives and the leather can be [[Haptic evaluation of leather surfaces|softened]] more easily. The [[tanning|tanning process]] is faster and requires less tanning chemistry than [[vegetable-tanned leather]]. | |

| − | + | Cost saving: Freshly tanned [[wet blue]] with its characteristic bluish tint is globally transportable and can be stored well. This facilitates unlimited international sales and global processing. | |

| Line 37: | Line 48: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | [[bild:Gerberei-Gerbfass-04.jpg| | + | [[bild:Gerberei-Gerbfass-04.jpg|500px]] |

| − | + | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | [[bild:Wet-Blue-06.jpg|500px]] |

| + | </p> | ||

| + | <p align=center> | ||

| + | ''Chrome tanning in the [[tanning leather#Tanning drum|tanning drum]].''<br></p> | ||

<p> </p> | <p> </p> | ||

| Line 47: | Line 60: | ||

{| class="prettytable right" | {| class="prettytable right" | ||

| − | |+''' | + | |+'''Proportion of chrome-tanned leather in various sectors of use''' |

| − | !bgcolor="#cccccc" | | + | !bgcolor="#cccccc" | Area || bgcolor="#cccccc" | Chrome-tanned leather in % || bgcolor="#cccccc" | tendency |

|- | |- | ||

| − | | [[ | + | | [[Leather shoes#Oberleder|Shoe upper leather]] |

|style="text-align: center"| 95 | |style="text-align: center"| 95 | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| No change |

|- | |- | ||

| − | | [[ | + | | [[Leather furniture|Furniture leather]] |

|style="text-align: center"| 70 | |style="text-align: center"| 70 | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| Decrease in favour [[Chrome tanned#Chrome-free leather - FOC = Free of Chrome|FOC-leather)]] |

|- | |- | ||

| − | | [[ | + | | [[Car leather]] |

|style="text-align: center"| 50 | |style="text-align: center"| 50 | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| Decrease in favour [[Chrome tanned#Chrome-free leather - FOC = Free of Chrome|FOC-leather)]] |

|- | |- | ||

| − | | [[ | + | | [[Leather clothing|Garment leather]] |

|style="text-align: center"| 100 | |style="text-align: center"| 100 | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| No change |

|- | |- | ||

| − | | [[ | + | | [[Leather handbags|Bags]], [[leather belt|belts]], [[Leather accessories|accessories]] |

|style="text-align: center"| 60 | |style="text-align: center"| 60 | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| No change |

|- | |- | ||

| − | | [[ | + | | [[Leather shoes#Sole leather|Sole leather]] |

|style="text-align: center"| - | |style="text-align: center"| - | ||

| − | |style="text-align: center"| | + | |style="text-align: center"| No change |

|} | |} | ||

| − | '' | + | ''Source: Journal leather & skins market - Leder & Häute Markt 3/2008, page 46.'' |

| Line 86: | Line 99: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''"[[Wet | + | ''"[[Wet blue]]" = damp, grey-bluish leather dyed right after chrome tanning by chromium.''<br></p> |

<p> </p> | <p> </p> | ||

| − | + | The chrome-tanning agent nearly always contains 33% basic chromium sulphate and 26% chromium (III) oxide. Annually 480,000 tonnes are produced in chrome tanning worldwide, which is about 125,000 tonnes of chromium (III) oxide. The use of chromium (III) salts is considered harmless to health and does not cause difficulties in the vast majority of people, despite intensive skin contact in footwear or apparel. Drinking water is allowed to contain 50 micrograms (chromium III) per litre. | |

| − | + | Major suppliers of chromium are South Africa with 38%, India 20%, Kazakhstan 15%, Turkey with 7%, Russia, Brazil and Zimbabwe each with 3% and Finland with 2%. Chromium III in nature: Earth's atmosphere contains 0.005-300 mg/kg, land plants contain 0.03-20 mg/kg or marine plankton contains 2.2-7.5 mg/kg and human bones 0.1-33 mg/kg. Only about 1% of the world production of chromium III is used for leather production. Steel contains 180-260 g/kg chromium III. | |

==Chrome-free leather - FOC = Free of Chrome== | ==Chrome-free leather - FOC = Free of Chrome== | ||

| − | + | FOC (free of chrome, chrome-free) labelled leather is [[tanning|tanned]] with [[tannins]] that do not contain chromium (III). They are now increasingly used in [[car leather|automotive upholstery]] and [[leather furniture|furniture upholstery]]. The [[car leather|leather seats of Audi and Porsche]] are always free of chrome. | |

| − | + | The production of FOC-leather is more complex than that of the chrome-tanned leather. For example, in the [[tanning|tanning process]], an exact temperature must be reached to tan successfully. FOC leather is mostly produced in developed countries. | |

| − | + | Frequently chromium-free leather is advertised with descriptions such as "without chromium and pollutants" or "heavy metal-free". This can give the impression that chrome tanning is harmful (heavy metal contamination), whereas tanning with chromium III is absolutely harmless. Many people associate "chrome" with toxic or may have read in the press about the transgressions involving content of [[Chrome VI - Chromium VI|chromium VI]]. Marketing campaigns for FOC leather usually exaggerate these fears. | |

| + | FOM (free of metal) is the name for leather that has been tanned completely without the use of metals and their compounds (such as aluminium, iron or titanium). | ||

| − | + | Currently, chromium tanning is extremely dominant. Alternative [[tanning|tanning methods]] are unable to replace it, mainly due to costs and technical considerations. Many [[vegetable-tanned leather|vegetable tanning agents]] occur naturally but they are not readily available in sufficient enough quantities yearly to satisfy the demand for [[leather industry|leather production worldwide]]. | |

| − | [[ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | Chrome-free [[tanning]] is being further developed worldwide and the proportion of chrome-free leather is constantly increasing, but the dominance of chrome tanning is still unbroken. | |

| − | |||

| − | + | ==[[Chrome VI - Chromium VI]]== | |

| + | [[Chrome VI - Chromium VI|Chromium (VI)]] is harmful and can occur in the leather as a result of improper tanning conditions. However, following thorough research, this can be avoided. | ||

| + | * [[Chrome VI - Chromium VI|For more information about chromium VI]] | ||

| − | |||

| − | + | ==Chrome tanning - Ecology== | |

| + | Environmental considerations with respect to chrome tanning are also important. The chromium-containing [[Wastewater from tanneries|waste water]] and waste materials must be recycled to recover valuable materials. Modern tanneries manage to bind up to 97% of the chromium used in the leather fibre, to keep the waste water load low and to save costs. | ||

| − | + | Correct disposal of chrome-tanned leathers is crucial. For example, [[car leather|leather seats]] in scrapped cars require appropriate handling because combustion of chrome-tanned leather can produce harmful [[Chrome VI - Chromium VI|chromium (VI)]]. Formation behaviour of chromium (VI) under conditions of high heat (bright sunlight on black [[car leather|car upholstery]] or [[Leather dashboard|dashboard leather]]) should also be reviewed regularly. | |

| − | + | Proponents of [[Vegetable-tanned leather|vegetable tanning]] argue that vegetable tanning agents are natural and chrome tanning agents are not, and also subtly or directly state that "chromium" is a toxic substance, which is not true of chromium(III). Conversely, it is argued that vegetable tanning agents use up natural resources and accelerate deforestation. However, it must be mentioned that in the 1950s twice as much vegetable tanning material was used by the [[tannery|tanneries]] because the demand for vegetable tanned leather was higher at the time. | |

| − | + | In several comparisons between chrome tanning, [[Vegetable-tanned leather|vegetable tanning]] and [[Synthetic tanned|synthetic tanning]], there were no relevant advantages of chrome-free tanning. All [[tanning|types of tanning]] are harmless for the workers in a [[tannery]] if they are carried out carefully, the waste materials can be disposed of without any problems and the [[leather waste]] from [[leather production]], the [[leather cutting waste]] from the leather processing companies and the disposal of leather objects after use are not hazardous waste materials. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

== Additional information == | == Additional information == | ||

| + | * [[Leather production]] | ||

| + | * [[Leather chemistry]] | ||

| + | * [[Wet blue]] | ||

* [[Chrome VI - Chromium VI]] | * [[Chrome VI - Chromium VI]] | ||

<br> | <br> | ||

| + | * [[Tannins]] | ||

* [[Vegetable-tanned leather]] | * [[Vegetable-tanned leather]] | ||

* [[Mineral tanning]] | * [[Mineral tanning]] | ||

| Line 144: | Line 151: | ||

* [[Brain tanning]] | * [[Brain tanning]] | ||

<br> | <br> | ||

| − | |||

* [[Bio leather]] | * [[Bio leather]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 169: | Line 158: | ||

<p align=center> | <p align=center> | ||

| − | <flashow> | + | <flashow>//www.youtube.com/v/-qn5R8dKcss&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow><br></p> |

<p align=center> | <p align=center> | ||

''The [[leather production]] in a modern [[tannery]].'' | ''The [[leather production]] in a modern [[tannery]].'' | ||

| Line 179: | Line 168: | ||

! bgcolor=#eeeeee | [[Tanning leather|Tanning]] methods | ! bgcolor=#eeeeee | [[Tanning leather|Tanning]] methods | ||

|- | |- | ||

| − | | bgcolor=#ffffff align=center | [[Chrome tanned|Chrome tanning]] - [[Vegetable-tanned leather]] - [[ | + | | bgcolor=#ffffff align=center | [[Chrome tanned|Chrome tanning]] - [[Vegetable-tanned leather]] - [[Synthetic tanned|Synthetic tanning]] - [[Tanning with fats and oils]] |

|} | |} | ||

</center> | </center> | ||

Latest revision as of 15:59, 20 June 2023

Contents

History of chrome tanning

Until the 19th century, there was little development in the tanning process. While there was some use of alum (aluminium) salts and other tanning methods, vegetable tanning was the most prevalent. In 1858, chrome tanning was invented by the German technologist Friedrich Knapp and Hylten Cavalin from Sweden. However, it was an American chemist called Augustus Schultz who first patented the chrome tanning process with alkaline chromium (III) sulfate as tanning agent.

Chromium(III) occurs naturally in the Earth's crust. It is often found in the form of chromium minerals such as chromite or chromite spinel. The largest deposits of chromite minerals are located in South Africa, Kazakhstan, India, Russia, Turkey, the Philippines, and Zimbabwe. Chromium(III) is extracted from these ores and converted into various compounds to fulfill its different applications.

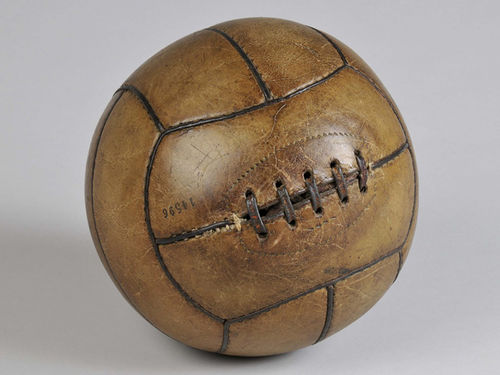

Beginnings of chrome tanning: Ball of chrome-tanned cow leather from before 1920 (© German Ledermuseum, C. Perl-Appl).

In the following decades, chrome tanning became the most common and dominant form of tanning. One of the main reasons why it was adopted so rapidly is that the process was much faster than vegetable tanning. In addition, the temperature resistance of chrome-tanned leather was an important factor in shoe manufacture. The vulcanization of rubber creates heat that chrome-tanned leather tolerates without shrinking. With chrome-tanned leather, the rubber soles could be vulcanized (connected) to the upper leather of the shoes without having to sew the sole to the upper leather. That was a big cost saving in industrial shoe manufacturing which is still valid today and cannot be achieved by other tanning methods. Another benefit of chrome-tanned leather was weight. Vegetable-tanned leather is stronger and heavier, but lightweight chrome-tanned leather was more popular for children's or women's shoes.

The invention of chrome tanning coincided with the discovery of the fatliquoring (regreasing) process and also the development of synthetic dyes. Together these changes to the chemistry of leather production led to chrome tanning becoming the preferred method. Chromium salts belong to the group of mineral tannins.

Immediately after tanning, the leather is still wet and is tinged with blue, hence it is also referred to as wet blue.

Chromium (III) oxide in powder form.

The global importance of chrome tanning

Chrome tanning with chromium (III) salts accounts for around 85 percent of global leather production (as per 2014). 95% of shoe upper leather, 70% of leather upholstery (but decreasing in favour of FOC-leather) and almost 100% of clothing leather are chrome tanned.

Although it has twice the tensile strength of vegetable tanned leather, chrome-tanned leather weighs less because the skin does not fully absorb the chromium salts used for tanning. The tannin makes up just 4% (with newer leathers only about 1.5%) of the leather weight, while vegetable-tanned leather has a tannin content of about 20 percent.

Chrome-tanned leather is more easily hydrophobized compared to other tanning alternatives and the leather can be softened more easily. The tanning process is faster and requires less tanning chemistry than vegetable-tanned leather.

Cost saving: Freshly tanned wet blue with its characteristic bluish tint is globally transportable and can be stored well. This facilitates unlimited international sales and global processing.

Chrome tanning in the tanning drum.

| Area | Chrome-tanned leather in % | tendency |

|---|---|---|

| Shoe upper leather | 95 | No change |

| Furniture leather | 70 | Decrease in favour FOC-leather) |

| Car leather | 50 | Decrease in favour FOC-leather) |

| Garment leather | 100 | No change |

| Bags, belts, accessories | 60 | No change |

| Sole leather | - | No change |

Source: Journal leather & skins market - Leder & Häute Markt 3/2008, page 46.

"Wet blue" = damp, grey-bluish leather dyed right after chrome tanning by chromium.

The chrome-tanning agent nearly always contains 33% basic chromium sulphate and 26% chromium (III) oxide. Annually 480,000 tonnes are produced in chrome tanning worldwide, which is about 125,000 tonnes of chromium (III) oxide. The use of chromium (III) salts is considered harmless to health and does not cause difficulties in the vast majority of people, despite intensive skin contact in footwear or apparel. Drinking water is allowed to contain 50 micrograms (chromium III) per litre.

Major suppliers of chromium are South Africa with 38%, India 20%, Kazakhstan 15%, Turkey with 7%, Russia, Brazil and Zimbabwe each with 3% and Finland with 2%. Chromium III in nature: Earth's atmosphere contains 0.005-300 mg/kg, land plants contain 0.03-20 mg/kg or marine plankton contains 2.2-7.5 mg/kg and human bones 0.1-33 mg/kg. Only about 1% of the world production of chromium III is used for leather production. Steel contains 180-260 g/kg chromium III.

Chrome-free leather - FOC = Free of Chrome

FOC (free of chrome, chrome-free) labelled leather is tanned with tannins that do not contain chromium (III). They are now increasingly used in automotive upholstery and furniture upholstery. The leather seats of Audi and Porsche are always free of chrome.

The production of FOC-leather is more complex than that of the chrome-tanned leather. For example, in the tanning process, an exact temperature must be reached to tan successfully. FOC leather is mostly produced in developed countries.

Frequently chromium-free leather is advertised with descriptions such as "without chromium and pollutants" or "heavy metal-free". This can give the impression that chrome tanning is harmful (heavy metal contamination), whereas tanning with chromium III is absolutely harmless. Many people associate "chrome" with toxic or may have read in the press about the transgressions involving content of chromium VI. Marketing campaigns for FOC leather usually exaggerate these fears.

FOM (free of metal) is the name for leather that has been tanned completely without the use of metals and their compounds (such as aluminium, iron or titanium).

Currently, chromium tanning is extremely dominant. Alternative tanning methods are unable to replace it, mainly due to costs and technical considerations. Many vegetable tanning agents occur naturally but they are not readily available in sufficient enough quantities yearly to satisfy the demand for leather production worldwide.

Chrome-free tanning is being further developed worldwide and the proportion of chrome-free leather is constantly increasing, but the dominance of chrome tanning is still unbroken.

Chrome VI - Chromium VI

Chromium (VI) is harmful and can occur in the leather as a result of improper tanning conditions. However, following thorough research, this can be avoided.

Chrome tanning - Ecology

Environmental considerations with respect to chrome tanning are also important. The chromium-containing waste water and waste materials must be recycled to recover valuable materials. Modern tanneries manage to bind up to 97% of the chromium used in the leather fibre, to keep the waste water load low and to save costs.

Correct disposal of chrome-tanned leathers is crucial. For example, leather seats in scrapped cars require appropriate handling because combustion of chrome-tanned leather can produce harmful chromium (VI). Formation behaviour of chromium (VI) under conditions of high heat (bright sunlight on black car upholstery or dashboard leather) should also be reviewed regularly.

Proponents of vegetable tanning argue that vegetable tanning agents are natural and chrome tanning agents are not, and also subtly or directly state that "chromium" is a toxic substance, which is not true of chromium(III). Conversely, it is argued that vegetable tanning agents use up natural resources and accelerate deforestation. However, it must be mentioned that in the 1950s twice as much vegetable tanning material was used by the tanneries because the demand for vegetable tanned leather was higher at the time.

In several comparisons between chrome tanning, vegetable tanning and synthetic tanning, there were no relevant advantages of chrome-free tanning. All types of tanning are harmless for the workers in a tannery if they are carried out carefully, the waste materials can be disposed of without any problems and the leather waste from leather production, the leather cutting waste from the leather processing companies and the disposal of leather objects after use are not hazardous waste materials.

Additional information

- Tannins

- Vegetable-tanned leather

- Mineral tanning

- Synthetic tanned

- Chamois leather

- Tawing with alum

- Brain tanning

Video about leather production

The leather production in a modern tannery.

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution