Difference between revisions of "Finish"

| Line 73: | Line 73: | ||

''The application of a pigment leather colour by [[Leather workshop|leather repair companies]] is carried out manually with a spray gun.''<br></p> | ''The application of a pigment leather colour by [[Leather workshop|leather repair companies]] is carried out manually with a spray gun.''<br></p> | ||

<p> </p> | <p> </p> | ||

| − | |||

[[Car leather]] was not [[leather colour#Dyed leather|dyed throug]] until the 70s, 80s. With some leathers, this lead to a beautiful [[Antique Leather - Vintage Leather#Leather patina|patina]]. | [[Car leather]] was not [[leather colour#Dyed leather|dyed throug]] until the 70s, 80s. With some leathers, this lead to a beautiful [[Antique Leather - Vintage Leather#Leather patina|patina]]. | ||

| Line 85: | Line 84: | ||

''Typical top pigmentation on un-dyed [[vegetable-tanned leather]] shimmers brownishly when getting [[Antique Leather - Vintage Leather#Leather patina|patina]].''<br></p> | ''Typical top pigmentation on un-dyed [[vegetable-tanned leather]] shimmers brownishly when getting [[Antique Leather - Vintage Leather#Leather patina|patina]].''<br></p> | ||

<p> </p> | <p> </p> | ||

| − | |||

Depending on the thickness of the applied pigment colouration, the [[smooth leather]] is referred to differently. No colour layer: [[Aniline leather]]. Little colour, but [[Leather hair pores - Hair follicles|hair pores]] still recognizable: [[Aniline leather, refined]] or [[Semi-aniline|semianilin leather]]. Much colour and [[Leather hair pores - Hair follicles|hair pores]] only little or not recognizable: Pigmented smooth leather. | Depending on the thickness of the applied pigment colouration, the [[smooth leather]] is referred to differently. No colour layer: [[Aniline leather]]. Little colour, but [[Leather hair pores - Hair follicles|hair pores]] still recognizable: [[Aniline leather, refined]] or [[Semi-aniline|semianilin leather]]. Much colour and [[Leather hair pores - Hair follicles|hair pores]] only little or not recognizable: Pigmented smooth leather. | ||

| Line 95: | Line 93: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Pure [[aniline leather]]: [[Leather hair pores - Hair follicles|Pores]] are completely visible and there is no | + | ''Pure [[aniline leather]]: [[Leather hair pores - Hair follicles|Pores]] are completely visible and there is no finish on the leather.''<br></p> |

<p> </p> | <p> </p> | ||

| Line 119: | Line 117: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | '' | + | ''Pigmented [[Smooth leather|smooth leather]]: [[Leather hair pores - Hair follicles|Pores]] |

are no longer distinguishable. The leather has a thick [[Leather colour|layer of paint]].''<br></p> | are no longer distinguishable. The leather has a thick [[Leather colour|layer of paint]].''<br></p> | ||

<p> </p> | <p> </p> | ||

Revision as of 21:39, 31 January 2017

Contents

Finish

The finishing of a leather determines the appearance of the final surface of the leather and the surface properties. This includes coloring, waterproofing, wax dressings, but also the mechanical processing steps such as the ironing or embossing of the leather.

Finishing with pigment containing leather colours

To make leather more durable, more stain-resistant and permanently water-repellent, a layer of a binder-pigment-mixture is applied to surface of smooth leather that has already been completely precoloured with aniline dyes. This color coat is also called finish or pigmentation. Motorcycle suits, but also many leisure jackets, shoes, car, furniture and bags made of smooth leather have this protective color layer. These leathers are then referred to as pigmented leather or finished leather.

Smooth leather without such colour layer is called aniline leather. Leather with a very thin finish is called aniline leather, refined or semianiline leather. Smooth leather with a layer thickness of more than 0.15 millimeters in color or foil must be declared as coated leather in Europe.

The advantage of aniline leather is a warm feel and naturalness. Disadvantage is the sensitivity. Pigmented leather feels colder and firmer, but is significantly easier to clean and care and less sensitive. Pigmented leathers also have lower breathability poperties than porous leather.

There are also leather which have an oil coating or wax coating. For these leathers, uncoloured or dyed waxes and / or oils are applied to the leather surface. Such leather is called pull-up leather.

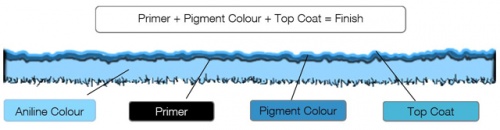

Primer - Finish / Top Coat

A primer is first applied as an adhesion promoter. The top coat, a kind of clear protective coating, is then applied to the subsequent color layer. Top Coats protects the binder color from abrasion and discolouration and determines the degree of gloss and the haptic. Crosslinkers provide improved fastnesses as additives. In case of particularly matt leather, a duller is added to the top coat and / or to the colour. Vehicle leather is often very matt and leather-covered dashboards must be particularly matt because of the risk of reflections in the front screen.

Video about different kinds of smooth leather.

Structure of the leather colouring and finish. Without finish = aniline leather.

A water drop on a pigmented smooth leather runs off. The pores of the leather are closed.

In the leather production, the pigmentation is applied by means of rotating spray guns.

The application of a pigment leather colour by leather repair companies is carried out manually with a spray gun.

Car leather was not dyed throug until the 70s, 80s. With some leathers, this lead to a beautiful patina.

Typical top pigmentation on un-dyed vegetable-tanned leather shimmers brownishly when getting patina.

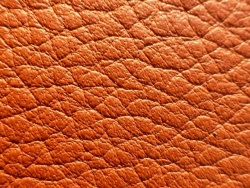

Depending on the thickness of the applied pigment colouration, the smooth leather is referred to differently. No colour layer: Aniline leather. Little colour, but hair pores still recognizable: Aniline leather, refined or semianilin leather. Much colour and hair pores only little or not recognizable: Pigmented smooth leather.

Pure aniline leather: Pores are completely visible and there is no finish on the leather.

Semi-aniline leather: Pores are clearly visible, but a thin layer of paint is on the leather surface.

Pores are hardly distinguishable. A stronger colour layer is on the leather surface. Only a leather consultant or expert can investigate whether this leather may still be referred to as semi-aniline leather.

Pigmented smooth leather: Pores

are no longer distinguishable. The leather has a thick layer of paint.

Problems with deficient finish

Die Zurichtung pigmentierter Leder kann variieren. Sie besteht aber meist aus einer Grundierung, einer Farbschicht und dem Top Coat (auch Appretur oder Finish genannt). Meist werden diese Schichten mit einem Vernetzer zusätzlich stabilisiert. Im Fall fehlerhafter Vorgehensweise kann das zu verschiedensten Problemen führen.

- Ist die Auftragsfäche vor dem Auftrag der Zurichtung mit einer Art Trennmittel versehen (Fette, Öle, Silikone ect.), dann kann es mit der Zeit zu Farbablösungen kommen.

- Die Zurichtung besteht aus mehrere Schichten. Sind die Wartezeiten zwischen den Schritten zu groß, kann es die Haftung der einen auf der anderen Schicht beeinträchtigen. Die Ablösung erfolgt dann nicht komplett, sondern zwischen einzelnen Schichten. Ursache kann eine Zwischenlagerung sein, bei der Trennmittel verwendet werden, die Verklebungen verhindern sollen. Grundsätzlich gilt aber immer, je frischer die letzte Schicht ist, desto besser haftet der folgende Schichtauftrag.

- Ist die aufgetragene Zurichtung zu weich, ist diese verschleißempfindich. Es kann zu Kratzern und Abschürfungen kommen oder die Zurichtung ist nicht abriebfest. Insbesondere Feuchtigkeit und Fette können solche Effekte verstärken. Da ein Leder im Idealfall weich und warm sein sollte, muss der Gerber die goldene Mitte finden.

- Ist der Top Coat zu dünn aufgetragen, kann es zu Farbabrieb kommen.

- Werden alle Schichten zu dick aufgetragen, wird das Leder sehr plastikartig und fühlt sich unnatürlich und kalt an.

- Fehlt der Vernetzer, ist die Zurichtung verschleißempfindlich.

- Ist die Zurichtung zu hart, kann das zu Graubruch führen. Beim Knicken des Leders gibt es Mikrobrüche, die das Leder gräulich erscheinen lassen. Meist in den Tiefen der Narbung.

- Zu weiche oder instabile Bindemittel können zu Klebrigkeit der Oberfläche führen. Lackleder neigen dazu, wenn diese älter werden. Aber auch Sonne kann diesen Effekt bei empfindlichen Ledern verstärkt herbeiführen.

- Wird ein Leder sehr matt eingestellt, kann es zu einem Grauschleier kommen.

- Sind die verwendeten Pigmente zu UV-empfindlich, bleicht das Leder aus.

- Empfindliche Bindemittel und andere Chemikalien der Zurichtung können vergilben.

- Verunreinigungen auf dem Leder während des Farbauftrags oder bei der Trocknung, können als Einschlüsse sichtbar werden.

- Eine dicke Schichtstärke auf zur Losnarbigkeit neigenden Ledern verstärkt diesen Effekt.

- Anilinfarbstoffe in der Zurichtung können migrieren oder abfärben.

- Amine aus Polsterschäumen oder NOX (Stickstoff, z.B. durch Abgase von Staplern in Lederlager) können gelbliche Veränderungen auf hellen Zurichtungen erzeugen.

Additional information

- Crackled leather - Crackle finished leather

- Metallic leather

- Ironing leather

- Glazing leather

- Gloss of leather

- Metamerism

- Micro hollow balls

Videos about the leather production

The leather production in a modern tannery.

Leather videos about the peculiarities of metallic effects on leather.

| Process steps in the leather production |

|---|

| storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - yeing (through colouring) and fatliquoring - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution