Horsehide - Horse leather

Contents

Horsehide - Horse leather

Horse leather is rare today. The horses in the fields were replaced by tractors and by motor vehicles as a means of transport. As a result, there is much less horse leather in the slaughterhouse. Horse meat is discredited because it has been found undeclared in food but, in principle, horse meat can be counted as normal, food as long as it is declared correctly.

Horse meat sandwich in Sicily (Italy), horse meat balls in Fulda (Germany).

Horse leather is traditionally used for shoes and clothing and is a smooth leather.

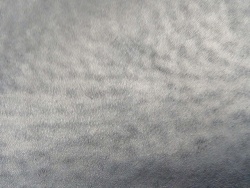

Horse aniline leather often has a special pattern due to the skin structure (www.leder-fiedler.de).

Pigmented horse leather is hardly distinguishable from bovine leather.

There are horses all over the world.

Cordovan - Horse leather shoes

Cordovan leather is mainly used for high-end shoes. Only the leather from the rear flanks of heavy workhorses is suitable. A few millimetres below the surface of the skin, there are two round pieces, which have a highly-compressed fibre structure (butt or shell). The leather is particularly dense and resistant in this area. Ready-produced cordovan contains a lot of grease and is therefore water repellent.

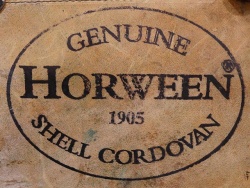

These pieces are about as big as a sheet of paper. Cordovan is one of the very expensive leathers, especially as the demand clearly exceeds the supply. Suitable horse skins are very rare, since heavy workhorses are also very rare and cannot be replaced by horses from breeding or sporting activities. The raw material therefore comes from a few specialist manufacturing companies. An American market leader in Cordovan production gets 75 percent of its skins from France and 25 percent from the Canadian province of Québec.

Shoes made of Cordovan (right from shoe maker Jacob, F. Schuhe (Shoes))

Cordovan leather has its roots in the United States, where its manufacturing process has been perfected over the years, while shoes made of this leather have been less frequent in Europe. Men's shoes made of Cordovan are therefore produced especially by American shoemakers.

Due to the vegetable tanning and the other production steps, the production time of Cordovan leather takes about six months. During the tanning process it becomes clearly visible which skin pieces can ultimately be used for shoe production and which are more suitable for wallets or leather belts. The skins are dried on glass for four days after 60 days of tanning and then wiped by hand with a special oil. This oil is completely absorbed into the leather during the next 90 days of storage.

A special feature of Cordovan leather is its fine gloss. This is produced by glazing at the end of the production process. Friction and heat create the characteristic effect which, however, can be destroyed by the use of incorrect shoe care products. Therefore, care for Cordovan shoes very carefully and only use the products recommended by the shoe or leather producer. Shoes from Cordovan have a very long life span if the production quality was good and if they are treated well.

The density of these Cordovan pieces and how the processing has been perfected is shown by the fact that the meat side is processed outwards. Nevertheless, the leather is very smooth and shiny at the end. There is no noticeable roughness. Only under the microscope can you see that the back of the leather is the visible surface, but the leather is stretchy and comfortable.

The gloss of the Cordovan leather reveals itself under the microscope as the back (flesh side) of the leather.

There are several theories about the origin of the term Cordovan. One of them is that it is derived from a French tanner family, which specialised in horse leather processing in a village of the same name. Other sources report that the Spanish city of Córdoba had already been a centre of leather production at the time of the Moors and that the village gradually became a generic name for goat leather and then for horse leather. In Germany, the term "Korduan" is used occasionally. The term Cordovan is common in English and Spanish.

A very nice video about the Cordovan leather production in the USA.

There are also leather shoes with normal smooth horse leather with grain side to the top. Under the microscope, the prominent pore structure of horse leather can be observed.

Horse leather has a different pore structure than Cow leather (below cow leather).

Horse leather shoes with grain side to the top.

Bags made of Cordovan horse leather

Briefcases are also made of Cordovan.

Briefcase made of horse leather from Horween - Shell Cordovan since 1905.

How to care for Cordovan horse leather

Even if Cordovan is particularly robust, there are important rules for cleaning and care, which apply only to this kind of leather.

Important: Cordovan cannot be cleaned with moisture. Wet cleaning makes the glazed fibres swell and they immediately become very dull and rough. Therefore, only dust off with a dry brush or cloth!

A classic leather care can also lead to the same result. Therefore, only products approved for Cordovan may be used. Cordovan can be maintained with COLOURLOCK GLOSS MILK. It retains the shine and protects against drying. Moisten a soft cloth with a little GLOSS MILK and apply it in circular movements without heavy rubbing. Then let dry on its own away from sources of heat. The resulting dullness is re-polished with a soft cloth. It is important to work sparingly and with little force. Always test first in a hidden area if possible.

Leather jackets made of horse leather

In addition to the use for shoes, horse leather is also processed into jackets. Since there is not much horse leather on the market, not many jackets are produced. Horse leather jackets have special characteristics: they are usually heavier and stiffer than other leather clothing and are heavily oiled or greased during the production of the leather. The surface of the leather jackets is smooth and without a notable grain structure. The design of the jackets is mostly in the style of early aviation jackets. Lovers of these leather jackets appreciate precisely these qualities. The leather becomes softer over time with use and gets a characteristic patina. Sometimes worn horse leather jackets get higher prices than new horse leather jackets.

Typical horse leather jackets from www.oldtimer-bekleidung.de.

Horse leather jackets are usually stiff and intensively oiled

But there are also very soft horse leather jackets. The company www.heinzbauer.com produces horse leather jackets where the leather is softened by a special washing process.

Soft horse leather jackets from www.heinzbauer.com.

Leather furniture made of horsehide

Furniture made of horse leather is rare. The area of the mane has been stylishly integrated into this furniture as a distinctive identification mark.

Horse leather furniture with recognisable area of the mane (seen at www.leder-fiedler.de).

Video about leather of different animal species

Leather of different animal species - Exotic leather.

Other exotic leather

- Alligator leather

- Alpaca fur

- Antelope leather

- Armadillo leather

- Bird leather

- Bull testicles

- Caiman leather

- Camel leather

- Carpincho leather

- Cat fur

- Chicken leather

- Crocodile leather

- Dog leather

- Donkey leather

- Elephant leather

- Fish leather: Eel, shark, salmon, moray eel, stingray and many others

- Frog leather - Toad leather

- Giraffe leather

- Hippo Leather

- Kangaroo leather

- Llama Fur

- Lizard leather

- Ostrich leather

- Pangolin leather

- Peccary leather

- Rumen leather

- Sealskin leather

- Snakeskin

- Turtle skin

- Walrus leather

- Yak leather

- Zebra hide

a kotori web solution

a kotori web solution