Leather dye - Leather color - Leather colour

Contents

- 1 Leather Colour - Leather Colour - Leather Dye

- 2 Dyed leather

- 3 Finish - Surface binder-based pigmentation

- 4 Painting on leather - Printing on leather

- 5 The colouring of the hair on hides and fur

- 6 Coated leather - Laminated leather

- 7 Additional information

- 8 Problems of leather colourations

- 9 Video about the colour restoration of leather colour damages

- 10 Video about colour separation of leather and dye transfer from leather

- 11 Video about the peculiarities of metallic effects on leather

- 12 Video about leather production

Leather Colour - Leather Colour - Leather Dye

The initial colour of a leather is dependent on the tanning agents used. Tannins of plants give the leather a brownish tone, fat and oil tanning makes leather yellowish, while tawing with alum and synthetic tanning agents give the leather a whitish tone and chrome tanning makes it bluish-greyish. After tanning, the leather is dyed to meet customer demand for colourful leather. In the colouration of leather, two main colouring methods are distinguished. The first process involves dyeing the leather with dyes and the second one involves pigmentation of the surface with binder-based colours. Since many other processes in leather production, such as e.g. If, for example, re-tanning influences leather coloring, the entire process must be controlled in such a way that the desired color result is achieved at the end.

Dyeing of the leather by chrome tanning, vegetable tanning or synthetic tanning.

Dyed leather

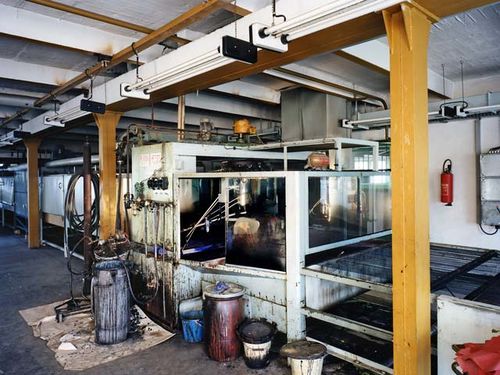

After tanning, most leather is first dyed through completely. This is done in dye stuff (liquid dye like ink for colouration of textiles). For this purpose, the leather is immersed in a dye bath in rotating barrels (= drum dyed). The dye has to be fixed and excess colour has to be rinsed out to prevent dye transfer from leather. The tannery buys the dyes for dyeing through as a powder or pre-dissolved as a liquid. Additives can be added to affect leather and color properties.

Aniline dye is a transparent liquid which is absorbed by the leather without forming a coating layer. All absorbent leather types (suede, nubuck and aniline leather) are dyed this way. Top-grained absorbent porous leather is called aniline. But also, most pigmented (with coating layer) leather is first dyed through.

Since these dyes are transparent, they can only be used to dye a darker shade. Aniline dye is usually referred to as "aniline colour". Previously, azo dyes were used as aniline paints. However, use of azo dyestuff (coal tar dyestuffs) is no longer allowed as it is harmful to health and is only found, if at all, in cheap imported leather goods.

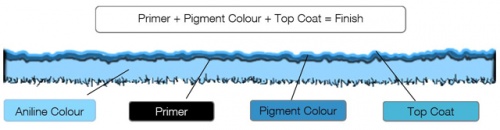

Components of the leather colouration and the finish.

Smooth leather, which does not receive any additional pigment-based colour layer on the surface, is called aniline leather. Such leather is dyed, but has no other protective colour layer on the surface.

Nubuck and suede are only dyed. Sometimes, patterns are printed and embossed on nubuck. In the area of printing, it is then pigmented and smooth. Such embossed nubuck was very popular with furniture in the 90s.

Smooth leather is dyed so that mechanical damages to the finish has a similar colour tone in the area of the damage. Such leather is called drum dyed. Where the surface colouration does not correspond well enough with the dyed through colour, or is ignored for reasons of cost, it is regarded as leather of poorer quality. Nevertheless, scratches are almost always visible due to the refraction in the area of damage. But with nearly the same colouration, it is less severe than in the case of deviant colourations.

Drum dyeing (1st photo by LEATHER NATURALLY).

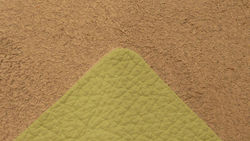

Non dyed through leather and dyed through leather.

These leathers were not dyed at all, or not suitable for dyeing.

Leather of better qualities are dyed to match the colouration of the finish.

Most leather has the same colour on top and inside. But deviations are sometimes desired. It is because the leather is multi-coloured (e.g., antique leather), or because it is a desired design element.

Typical antique leather.

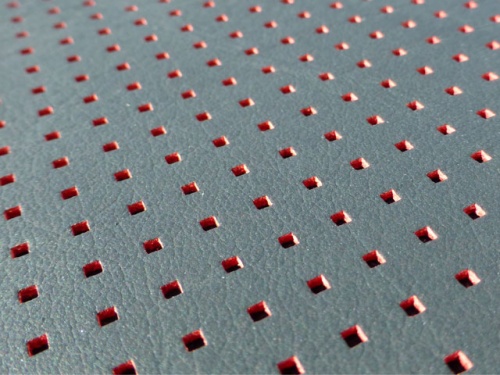

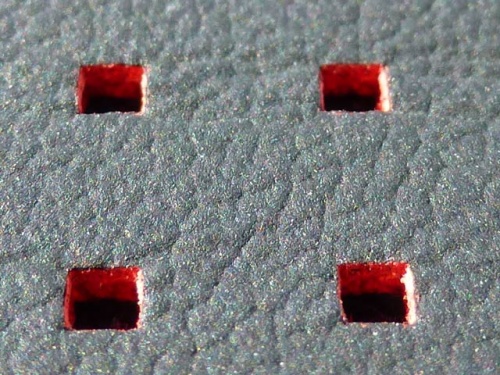

Wish of the designer: Perforated red leather with a black surface pigmentation.

Leather damages always become visible. Only with strong contrasts is it a deterioration.

In the time of vegetable-tanned leather, the non dyed through colouration resulted in beautiful patina effects, which the more modern leathers no longer have.

Vegetable-tanned, only top pigmented classic car leather with patina. - Modern car leather with damages from use.

Signs of wear are always visible. Colouration throughout does not prevent this.

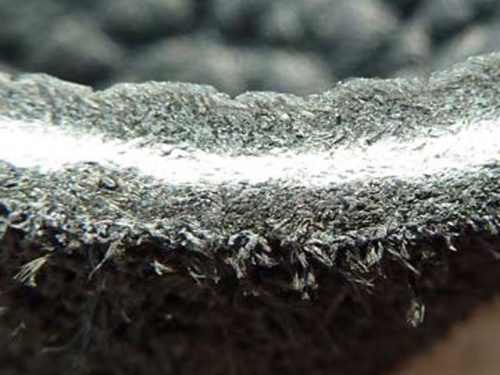

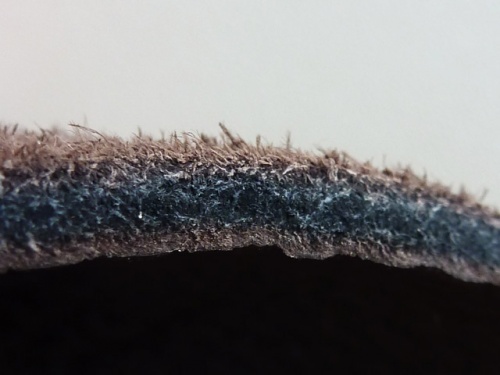

This leather is not dyed throughout. That is normal for thick leather and not a sign of bad leather quality.

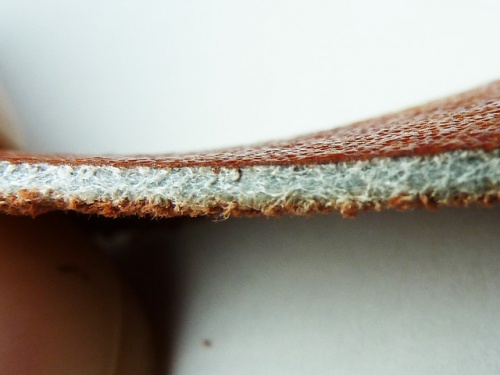

This leather is not dyed through. The dye was only sprayed on the top. This is a sign for cheap and low quality leather.

This leather was first dyed black and afterwards dyed dark brown. This is a rare method. The reason may have been the reuse of leftover black dyed leather.

Extreme case: This sheep leather jacket was first sewn and then the white leather was coloured grey. The post-corrections are very spotty.

Finish - Surface binder-based pigmentation

Pigmented smooth leathers are leathers where the surface is covered with a layer of pigments and binders to achieve a uniform and opaque color.

The particle size of the pigments in pigmented smooth leathers plays an important role in the opacity and uniformity of the leather's color. Smaller pigment particles enable a finer and more even distribution of color, giving the pigmented leather a more natural appearance and a more natural feel.

In particular, stressed leather and leather which can get wet and dirty easily is treated with a protective pigment layer on the surface after the dyeing. This is usually sprayed on, rolled on with a roller coater and, in rare cases, applied manually. Almost all car leather, furniture leather, but also bags, clothing and shoe leather often have a protective pigment layer on top of the grain side. This pigmentation is usually recognised by the fact that a drop of water rubbed into the leather does not penetrate the surface.

Heavily pigmented leather is waterproofed by the binder-based colour layer.

Colouring old and damaged leather in the workshop. In the tannery it is dyed with rotating spray heads.

Depending on the thickness of the applied pigment layer, smooth leather is referred to differently.

- No pigment based top colouration: Aniline leather

- Little pigmentation, but hair pores still well recognisable: Semi-aniline

- Thick colouration and hair pores only little or not recognisable: Pigmented leather.

Aniline leather may have a pigment-free coating of a maximum thickness of 0.01 mm (= 10 micrometre). A normal pigmentation has a thickness of 0.035 to 0.04 mm. For automotive leather, the thickness of the colour layer is 0.1 mm. Above 0.15 mm thickness of the coat, the leather must be referred to as "coated leather".

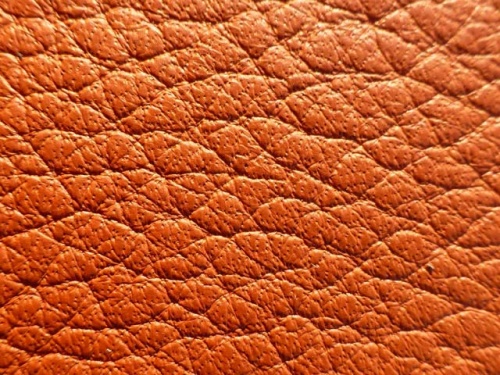

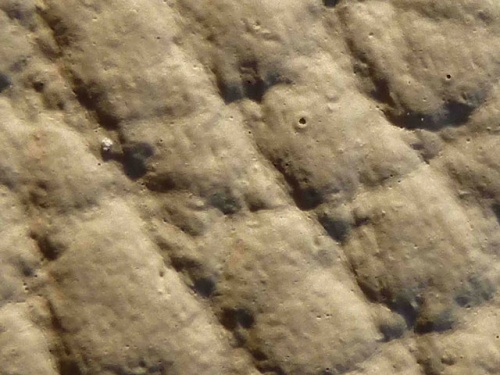

Pure aniline leather: Pores are completely recognisable and there is no finish on the leather.

Semi-aniline leather: Pores are clearly visible, but a thin layer of paint is on the leather surface.

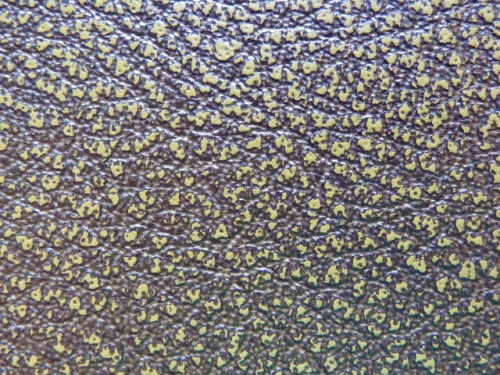

Pores are hardly recognisable. A heavy colour layer is on the leather surface. Only a leather consultant or expert can investigate whether this leather still may be referred to as semi-aniline leather.

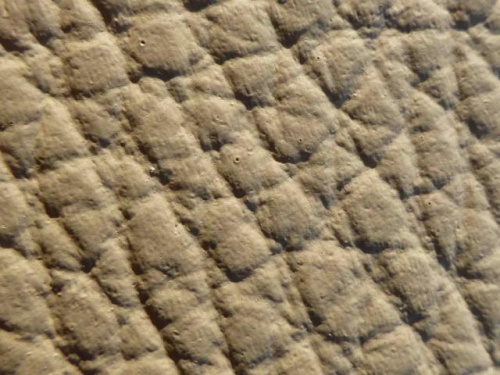

Pigmented smooth leather: Pores

are no longer recognisable. A thick layer of paint is on the leather.

With pigments, almost all leather paints can be mixed. There are leather colours with luminous effects or metallic effects. A transparent protective coating called Top Coat, is also applied onto the pigment layer. It controls the resistance and gloss of the leather. A pigment layer on a leather makes it less soft. A pigmented leather feels colder. Therefore, the tanner always has to decide whether the leather should be easy to maintain or be haptically beautiful. It isn't possible to have a leather that is both "buttery soft" and "easy to maintain" at the same time according to the present state of the technology.

Most pigmented leather is still dyed through in the same shade under the pigmentation. This is done to prevent signs of use having too much contrast. However, the optical perception of wear cannot be completely prevented.

Basic colours of pigment-based colours for leather (available at www.colourlock.com).

Luminous leather colours (available at www.colourlock.com). Luminous colours are used for leather suits.

Due to metal effects as an additive to the Top Coat, the leather colour has a metallic shimmer (available at www.colourlock.com).

Innovation Award 2022 | COLOURLOCK Leather Colours.

Colourful colouring in the leather workshop.

Painting on leather - Printing on leather

There are various opportunities for designing leather with colour. Leather can be printed, it can be painted, but also laser, etching and tattooing is used.

Painted leather chair of Torsten Russ www.torstenruss.de and a printed leather shoe.

The colouring of the hair on hides and fur

The leather cannot only be dyed or coated with colour, but also the hair in the skin can be coloured for design purposes. The hair side of cowhides is usually processed this way.

Coloured hair of a cowhide.

Coated leather - Laminated leather

In some manufacturing processes, coloured films are adhered to the leather. This procedure is carried out on patent leather or PU-leather.

Rather cheap leather is foil-coated.

Additional information

- Painting on leather

- Printing on leather

- Crackled leather - Crackle finished leather

- Metallic leather

- Ironing leather

- Glazing leather

- Gloss of leather

- Metamerism

Problems of leather colourations

- Leather with stains caused by glue migration

- Dye transfer from leather

- Colour separation of leather

- Typical PU leather damages

- Flamingo effect: Reddish discolouration with light furniture leather in hidden areas

- Bronzing: Metallic glimmer on new leather

Video about the colour restoration of leather colour damages

Colour refreshments for car, furniture and bag leather

![]() -> COLOURLOCK - TREATMENT OF FURNITURE LEATHER

-> COLOURLOCK - TREATMENT OF FURNITURE LEATHER

![]() -> COLOURLOCK - REPAIRING COLOUR DAMAGES ON CAR LEATHER

-> COLOURLOCK - REPAIRING COLOUR DAMAGES ON CAR LEATHER

![]() -> COLOURLOCK - TREATMENT OF LEATHER CASES AND BAGS

-> COLOURLOCK - TREATMENT OF LEATHER CASES AND BAGS

![]() -> In German: www.lederzentrum.de

-> In German: www.lederzentrum.de

![]() -> Rest of the world: partners worldwide

-> Rest of the world: partners worldwide

Video about colour separation of leather and dye transfer from leather

Video about the peculiarities of metallic effects on leather

Video about leather production

The leather production in a modern tannery.

a kotori web solution

a kotori web solution